記事ナビゲーション

- Introduction: Revolutionizing Stone Quarrying with the DTH Drilling Machine

- Core Principles: How the Hydraulic Pneumatic DTH Machine Works

- Key Features and Advantages of the DTH Drilling Machine in Quarrying

- Versatile Applications of the DTH Machine for Various Stone Quarries

- Comprehensive FAQ: Your Questions on the DTH Drilling Machine Answered

- Conclusion: The Indispensable Role of DTH Drilling Technology in Modern Quarrying

Introduction: Revolutionizing Stone Quarrying with the DTH Drilling Machine

In the demanding world of dimensional stone extraction, efficiency, precision, and minimal material waste are not just goals—they are necessities for profitability and sustainability. The industry constantly seeks advanced technologies that can meet these challenges head-on.

Defining the Modern Quarrying Solution

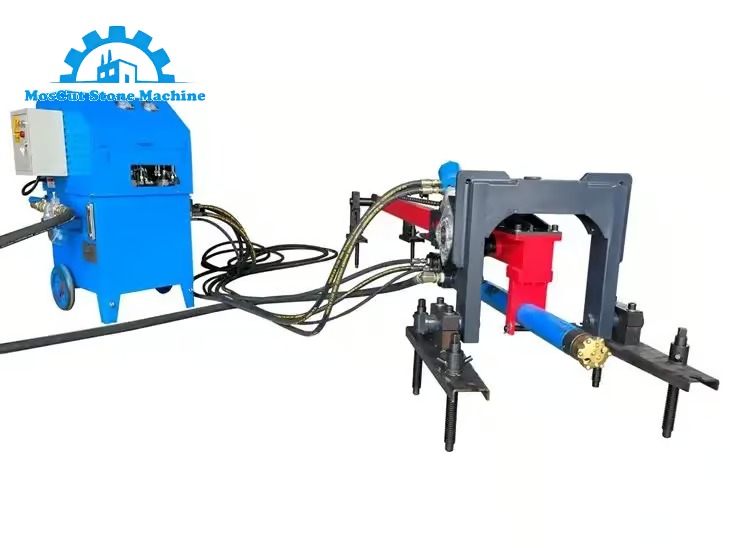

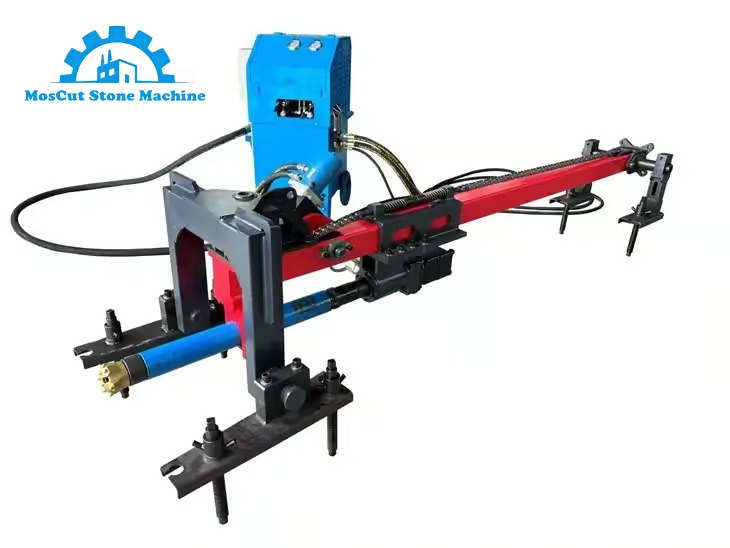

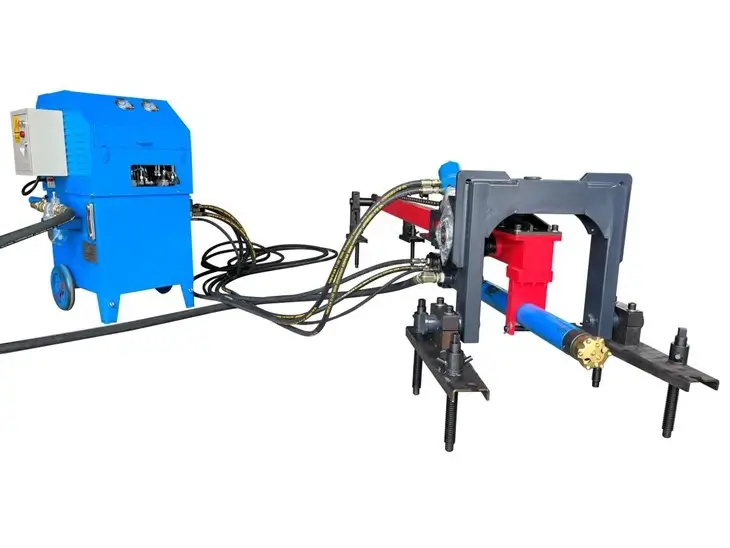

At the forefront of this technological evolution is the Hydraulic Pneumatic DTH Drilling Machine. This powerful piece of auxiliary equipment represents a significant leap forward from traditional drilling methods. It is an ingeniously engineered system that combines the immense, controlled power of hydraulics with the efficient, high-impact energy of pneumatics to deliver unparalleled performance in stone quarrying operations. This machine is specifically designed to create deep, precise, and clean boreholes in the toughest natural stones.

The Core Technology: A Synergy of Power

What sets this equipment apart is its unique dual-power design. The 水理 system provides the robust rotational torque and steady, powerful feed force needed to drive the drill string. Simultaneously, the pneumatic system serves a dual purpose: it powers the "Down-The-Hole" (DTH) hammer that delivers rapid, direct impacts to the drill bit at the bottom of the hole, while also flushing out drill cuttings with high-pressure air. This DTH action ensures maximum energy transfer for faster penetration rates, especially in hard rock.

Unmatched Versatility in Operation

The versatility of this Drilling Machine is a key benefit for modern quarries. It is engineered to perform not just vertical drilling but also horizontal and angled drilling with high precision. This flexibility is crucial for various stages of stone quarrying, from primary block separation to secondary splitting, making it an indispensable tool for extracting marble, granite, limestone, and sandstone with minimal waste and maximum yield.

What This Article Covers

This article will provide a comprehensive overview of the Hydraulic Pneumatic DTH Drilling Machine. We will delve into its detailed working principles, break down its key components and features, and explore its specific applications across different types of stone quarries. Finally, an extensive FAQ section will address practical questions about investment, operation, maintenance, and more, providing a complete guide for anyone involved in or considering this advanced technology for Stone Quarrying.

Core Principles: How the Hydraulic Pneumatic DTH Machine Works

Understanding the fundamental operating principles of the Hydraulic Pneumatic DTH Drilling Machine is key to appreciating its superior performance in demanding quarry environments. This section breaks down the sophisticated technology that makes this equipment so effective for modern stone quarrying オペレーションを行う。

The "Down-The-Hole" (DTH) Advantage Explained

At the heart of this technology is the DTH hammer—a revolutionary component that sets it apart from conventional drilling systems. Unlike top-hammer drills where impact energy must travel through the entire drill string, the DTH hammer is positioned directly behind the drill bit, at the bottom of the hole. This placement ensures that the percussive energy is delivered directly to the rock with minimal loss, resulting in significantly higher drilling efficiency and faster penetration rates, especially in hard stones like granite.

Hydraulic Power: The Driving Force Behind the Machine

について 水理 system serves as the primary power source for this advanced Drilling Machine. It performs two critical functions: first, it drives the powerful hydraulic motor that rotates the drill string and bit at optimal speeds. Second, it controls the feed system, applying consistent and adjustable downward pressure (thrust) to advance the drill bit into the rock. This precise control over rotation and feed force allows operators to maintain optimal drilling parameters for different stone types encountered in quarrying オペレーションを行う。

Pneumatic System: Dual-Purpose Efficiency

について pneumatic component of this system is equally ingenious. High-pressure compressed air is channeled down the hollow drill rods to achieve two vital tasks simultaneously. Primarily, it activates the DTH hammer, causing it to deliver rapid, powerful blows to the drill bit. Concurrently, the same airflow serves as an efficient cleaning mechanism, forcefully ejecting rock cuttings and dust from the borehole. This continuous flushing action keeps the drill bit cool, prevents jamming, and ensures a clean, accurate hole—a crucial feature for precision work in stone extraction.

The Complete Drilling Cycle: From Setup to Completion

The operational cycle of this Hydraulic Pneumatic system is a symphony of coordinated actions. It begins with positioning the rig on the stone surface. Once activated, the 水理 motor initiates rotation while the feed system applies thrust. Simultaneously, compressed air is sent down the drill pipe to power the DTH hammer and clear debris. This combined rotary-percussive action, powered by the dual 水理 そして pneumatic systems, continues until the desired depth is achieved. The machine then retracts the drill string, ready for the next operation. This efficient cycle makes the machine exceptionally productive for various stone quarrying applications.

Key Features and Advantages of the DTH Drilling Machine in Quarrying

について Hydraulic Pneumatic DTH Drilling Machine stands out in the competitive quarry equipment market due to its unique combination of advanced features that deliver tangible benefits. This section explores the specific characteristics that make this equipment an invaluable asset for efficient stone quarrying は世界中で事業を展開している。

Exceptional Drilling Efficiency and Speed

The innovative DTH technology is engineered for maximum productivity. By positioning the hammer mechanism directly at the drill bit, energy transfer is optimized with minimal loss. This direct impact results in significantly faster penetration rates compared to conventional drilling methods. The powerful 水理 system ensures consistent rotation and feed pressure, while the pneumatic flushing keeps the borehole clean, allowing for continuous, uninterrupted drilling operations that dramatically increase overall productivity in demanding quarry environments.

Superior Precision and Hole Quality

Precision is paramount in dimensional stone extraction, and this Drilling Machine delivers exceptional accuracy. The stable 水理 feed system maintains perfect alignment, producing straight holes with minimal deviation. This precision is crucial for creating clean separation lines in valuable stone blocks, significantly reducing material waste and maximizing yield from each quarry block. The consistent hole quality achieved by this DTH system ensures better performance when using secondary splitting methods like feather and wedge or hydraulic splitters.

Unmatched Versatility Across Stone Types

One of the most significant advantages of this Hydraulic Pneumatic equipment is its remarkable adaptability. The machine's power and control parameters can be optimized for various hardness levels, making it equally effective in soft limestone, medium-hard sandstone, and extremely hard granite. The robust DTH hammers and drill bits are specifically designed to withstand the abrasive nature of different stones, ensuring consistent performance across diverse quarrying applications. This versatility makes it a single-solution equipment for operations that extract multiple stone types.

Enhanced Operational Flexibility and Positioning

The design of this advanced Drilling Machine provides exceptional operational flexibility. Its modular construction and adjustable mounting systems allow for easy configuration in various orientations—vertical, horizontal, or any angle in between. This capability is essential for complex quarrying operations where drilling direction must adapt to the natural bedding planes of the stone. The equipment's ability to perform multi-directional drilling eliminates the need for multiple specialized machines, streamlining operations and reducing equipment costs for comprehensive stone quarrying projects.

Economic and Environmental Benefits

Beyond pure performance metrics, this Hydraulic Pneumatic DTH Drilling Machine delivers substantial economic and environmental advantages. The non-explosive nature of the drilling method preserves the integrity of the natural stone, dramatically reducing waste and increasing the percentage of usable material. Lower vibration levels minimize the risk of micro-fractures in sensitive stones like marble. Additionally, the efficient pneumatic dust control system creates a cleaner, safer working environment while reducing environmental impact. These factors combine to deliver a faster return on investment through higher yields, reduced material costs, and improved operational safety in modern quarry operations.

Versatile Applications of the DTH Machine for Various Stone Quarries

The true value of the Hydraulic Pneumatic DTH Drilling Machine is demonstrated through its diverse applications across different quarrying scenarios and stone types. This section explores how this versatile equipment addresses the unique challenges presented by various stones and quarrying methods, making it an essential tool for modern stone quarrying は世界中で事業を展開している。

Granite Quarrying: Powering Through Extreme Hardness

Granite presents one of the toughest challenges in stone quarrying due to its exceptional hardness and abrasive qualities. The Hydraulic Pneumatic DTH Drilling Machine excels in these demanding conditions. The powerful DTH hammer delivers concentrated impact energy directly to the granite surface, while the robust 水理 system maintains consistent pressure and rotation. This combination allows for efficient drilling in even the hardest granite formations, making it ideal for primary block separation and secondary splitting operations. The precision of this Drilling Machine ensures minimal material waste, maximizing the yield from these valuable stone deposits.

Marble Extraction: Precision for Premium Stone

In marble quarries, where the value of the stone demands extreme care and precision, the controlled operation of the Hydraulic Pneumatic system proves invaluable. Unlike more aggressive methods that can cause micro-fractures or damage to the delicate veining, this DTH Drilling Machine offers gentle yet effective penetration. The adjustable 水理 pressure allows operators to fine-tune the drilling force to match the specific characteristics of the marble formation. This precision drilling capability is essential for creating clean separation lines that preserve the integrity and value of premium marble blocks, making it the preferred choice for high-value stone quarrying オペレーションを行う。

Sandstone and Limestone Quarrying: Efficiency in Soft to Medium Stone

While sandstone and limestone are generally softer than granite or marble, they present their own unique challenges, including abrasiveness and variable density. The Hydraulic Pneumatic DTH Drilling Machine adapts perfectly to these conditions. The efficient pneumatic flushing system effectively removes loose material from sandstone boreholes, preventing bit binding and ensuring smooth operation. For limestone formations, the adjustable impact energy of the DTH system prevents over-breaking while maintaining high drilling speeds. This adaptability makes the Drilling Machine equally valuable in softer stone quarries, where productivity and hole quality remain critical to operational success.

Primary Block Separation: The First Critical Step

One of the most critical applications of the Hydraulic Pneumatic DTH Drilling Machine is in primary block separation from the quarry face. The equipment's ability to drill deep, precisely aligned holes in various orientations makes it ideal for creating the initial separation lines. Operators use the Drilling Machine to create a series of closely spaced holes along predetermined fracture lines. The precision of the DTH system ensures these holes are perfectly aligned, facilitating clean separation when using secondary methods like wire saws or expanding agents. This application demonstrates the machine's crucial role in the initial phase of the stone quarrying プロセスだ。

Secondary Splitting and Dimensioning: Maximizing Stone Value

After primary blocks are extracted, the Hydraulic Pneumatic DTH Drilling Machine continues to add value through secondary operations. The machine is used to drill holes for feather and wedge systems or hydraulic splitters that break large blocks into smaller, marketable sizes. The accuracy of the DTH drilling ensures controlled fractures along desired planes, minimizing waste and maximizing the yield of high-value slabs. The flexibility of this Drilling Machine to operate in horizontal, vertical, and angled positions makes it indispensable for these precision splitting operations, demonstrating its versatility throughout the entire stone quarrying workflow.

Specialized Quarrying Applications

Beyond standard block extraction, the Hydraulic Pneumatic DTH Drilling Machine finds application in various specialized quarrying tasks. These include drilling holes for anchoring systems in unstable quarry walls, creating drainage channels in quarry floors, and preparing holes for blasting operations in rare cases where controlled explosives are permitted. The robust 水理 system and efficient DTH technology make this equipment adaptable to numerous challenging scenarios encountered in modern stone quarrying operations, further enhancing its value as a multi-purpose investment for quarry operators.

Comprehensive FAQ: Your Questions on the DTH Drilling Machine Answered

This comprehensive FAQ section addresses the most common questions about the Hydraulic Pneumatic DTH Drilling Machine, covering everything from initial investment to daily operation and maintenance. Whether you're considering purchasing this equipment or seeking to optimize your existing stone quarrying operations, you'll find valuable insights here.

Cost and Investment Questions

Q1: What is the price range for a hydraulic pneumatic DTH drilling machine?

The price of a Hydraulic Pneumatic DTH Drilling Machine typically ranges from $10,000 to $20,000, depending on the drilling capacity, power rating, and additional features. Smaller models for light quarrying work start around $10,000, while heavy-duty machines capable of drilling large diameter holes in hard granite can cost $20,000 or more.

Q2: What factors most affect the final price of a DTH machine?

Several factors influence the cost, including drilling depth capacity, hole diameter range, power source configuration, brand reputation, and included accessories. The quality of the DTH hammer and drill bits also significantly impacts the price, as premium components ensure better performance and longer service life in demanding stone quarrying applications.

Q3: Is leasing or buying a better option for a new quarry operation?

For established operations with consistent workload, purchasing usually provides better long-term value. However, new quarries or those with fluctuating projects might benefit from leasing a Hydraulic Pneumatic DTH Drilling Machine initially to test its suitability before making a full investment.

Performance and Application Questions

Q4: What is the maximum drilling depth achievable with a standard DTH machine?

Standard Hydraulic Pneumatic DTH Drilling Machines にとって stone quarrying typically achieve depths of 20-30 meters, though specialized models can reach 50 meters or more. The actual depth depends on the rock hardness, drill rod length, and the specific DTH hammer configuration.

Q5: How does the DTH machine compare to traditional drilling methods?

について Hydraulic Pneumatic DTH Drilling Machine offers significant advantages over traditional top-hammer drills, including higher penetration rates, better energy efficiency, straighter holes, and reduced noise levels. The DTH technology delivers impact energy directly to the rock face, minimizing energy loss through the drill string.

Q6: Can this machine handle both vertical and horizontal drilling in quarry operations?

Yes, one of the key advantages of this Drilling Machine is its versatility. The robust 水理 system and stable mounting design allow for precise drilling in vertical, horizontal, and angled orientations, making it ideal for various stone quarrying applications from bench drilling to slot drilling for block separation.

Operation and Maintenance Questions

Q7: What training is required to operate a DTH drilling machine safely?

Operators should receive comprehensive training covering 水理 そして pneumatic system operation, safety protocols, routine maintenance, and troubleshooting. Most reputable suppliers offer onsite training programs specifically designed for their DTH Drilling Machine models to ensure safe and efficient operation in quarry environments.

Q8: What daily maintenance does the machine require?

Daily maintenance includes checking hydraulic fluid levels, inspecting air filters, greasing all moving parts, examining drill rods and bits for wear, and testing safety systems. The pneumatic system requires particular attention to moisture traps and air line integrity to ensure optimal DTH hammer performance.

Q9: How often do DTH hammers and drill bits need replacement?

The service life of DTH hammers and bits varies significantly based on rock hardness and operating conditions. In granite quarries, bits may last 200-400 meters of drilling, while in softer limestone, they can achieve 800+ meters. Regular inspection and proper operation are key to maximizing component lifespan in stone quarrying applications.

Technical and Support Questions

Q10: What is the typical warranty period for a hydraulic pneumatic DTH drill?

Most manufacturers offer a 12-month warranty on the complete Hydraulic Pneumatic DTH Drilling Machine, with shorter coverage (typically 3-6 months) on wear parts like DTH hammers and drill bits. Extended warranty options are often available for comprehensive protection in demanding stone quarrying オペレーションを行う。

Q11: How available are replacement parts for these machines?

Replacement parts for reputable DTH Drilling Machine brands are generally readily available through global distributor networks. Common wear parts like seals, filters, and even complete DTH hammers are typically stocked for quick shipment to minimize downtime in quarry operations.

Q12: What technical support is typically provided with purchase?

Reputable suppliers provide comprehensive technical support including installation supervision, operator training, troubleshooting assistance, and regular maintenance guidance. Many also offer remote diagnostics and 24/7 support hotlines to ensure continuous operation of your Hydraulic Pneumatic DTH Drilling Machine in critical stone quarrying applications.

The Indispensable Role of DTH Drilling Technology in Modern Quarrying

As we've explored throughout this comprehensive guide, the Hydraulic Pneumatic DTH Drilling Machine represents a transformative technology that has redefined efficiency and precision in contemporary stone quarrying operations. This concluding section summarizes the key takeaways and underscores why this equipment has become an essential investment for competitive quarry businesses worldwide.

Summarizing the Core Advantages of DTH Technology

について Hydraulic Pneumatic DTH Drilling Machine combines the best of both power systems to deliver unmatched performance. The robust 水理 system provides the necessary rotational torque and feed force, while the efficient pneumatic mechanism powers the DTH hammer and ensures effective hole cleaning. This synergy results in faster drilling speeds, superior hole accuracy, and reduced operational costs—benefits that directly translate to enhanced profitability in stone quarrying enterprises. The versatility of this Drilling Machine across different stone types and operational orientations further solidifies its value proposition.

The Economic Impact on Quarry Operations

Investing in a high-quality Hydraulic Pneumatic DTH Drilling Machine delivers substantial economic benefits throughout the quarrying process. The precision of the DTH system minimizes stone waste by creating clean separation lines, significantly increasing the yield of valuable stone blocks. Reduced material waste, combined with higher drilling efficiency and lower labor costs, results in a compelling return on investment. Furthermore, the non-explosive nature of this Drilling Machine preserves the structural integrity of the stone, ensuring higher quality end products that command better market prices—a crucial advantage in today's competitive stone industry.

Environmental and Safety Considerations

Beyond economic factors, the Hydraulic Pneumatic DTH Drilling Machine offers significant environmental and safety advantages that align with modern sustainable quarrying practices. The equipment generates less noise and vibration compared to alternative methods, creating a safer working environment while reducing the environmental impact on surrounding areas. The efficient pneumatic dust control system minimizes airborne particles, protecting both workers and the local ecosystem. These environmental benefits, combined with the machine's ability to maximize stone recovery from each quarry site, make the DTH Drilling Machine an environmentally responsible choice for forward-thinking stone quarrying オペレーションを行う。

Future-Proofing Your Quarrying Operations

As the global stone industry continues to evolve, embracing advanced technologies like the Hydraulic Pneumatic DTH Drilling Machine becomes increasingly important for maintaining competitive advantage. This equipment represents more than just a tool—it embodies a modern approach to stone quarrying that prioritizes efficiency, precision, and sustainability. The modular design and continuous technological improvements in DTH systems ensure that this equipment will remain relevant and valuable as quarrying techniques advance. By integrating this technology into their operations, quarry owners position themselves at the forefront of industry innovation, ready to meet future challenges and opportunities in the dynamic global stone market.

Final Recommendation for Quarry Professionals

For quarry operators and managers considering equipment upgrades or expansions, the Hydraulic Pneumatic DTH Drilling Machine warrants serious consideration. Its proven performance across diverse applications—from granite and marble to limestone and sandstone—makes it a versatile solution for various quarrying scenarios. When selecting a Drilling Machine, prioritize models from reputable manufacturers that offer comprehensive technical support, readily available spare parts, and operator training programs. The initial investment in a quality Hydraulic Pneumatic DTH system will yield long-term dividends through increased productivity, reduced operational costs, and enhanced stone recovery rates, ultimately strengthening your position in the competitive stone quarrying industry.