1. Machine Decsription

2. How does a Automatic Horizontal Stone Edge Polishing Machine work

3. Machine Features

4. Machine Details Show

5. Machine Specifications

Machine Decsription

The stone industry has seen a tremendous change in the past few years, with the introduction of automatic stone edge polishing machines. These machines have revolutionized the way stones are processed and polished, making the task easier, faster, and more efficient. An automatic stone edge polishing machine is a machine that is designed to polish the edges of stone slabs automatically. The machine is equipped with multiple polishing heads that move along the edges of the stone slab, polishing it to a smooth and glossy finish. 20 heads horizontal stone edging machines for rough grinding, fine grinding and polishing of the straight bottom of all stones. The straight line edge polishing machine is working on vertical way while this machine is working with horizontal way. This machine adopts stepless speed regulation, the worktable roller assists feeding, the crawler rubber clamp transmits the stone, the motor is electrically adjusted, and the pneumatic compensation.The horizontal stone edging machine is highly efficient and environmentally friendly, and the automated production mode adopted can meet the needs of customers for the production of stone wire types, and the processed products meet international standards. 20 head stone automatic horizontal stone edging machine is suitable for edge processing on quartz, seamless reversal of slate, granite, marble and other materials, up and down R round belt side throw, fixed thickness belt polishing, up and down chamfer belt side edge polishing, large bevel edge, horse The upper and lower sides of the belly and horse belly are line-shaped. The automatic edge polishing machine adopts numerical control, equipped with PLC panel, which can be automatically compensated, the angle can be adjusted arbitrarily, and the frequency conversion speed regulation.

How does a Automatic Horizontal Stone Edge Polishing Machine work

The automatic stone edge polishing machine works by using a series of polishing heads that move along the edges of the stone slab, removing any rough edges and polishing it to a smooth and glossy finish. The machine is computer-controlled, which means that the operator can program it to polish the stone slab to a specific shape and size.

Polishing Size

- Automatic stone edge polishing machines come in different sizes and configurations, depending on the size and thickness of the stone slabs they are designed to polish. Some machines are designed for small and medium-sized slabs, while others are designed for large and heavy slabs.

Polishing Heads

- The polishing heads of the machine can be equipped with different types of abrasive tools, such as diamond pads or resin discs, depending on the type of stone being polished and the desired finish.

Polish Shapes

- The machine can be programmed to polish the edges of the stone slab to a specific shape and size, such as a straight edge, a bullnose edge, or an ogee edge. This means that the machine can produce a wide range of edge profiles, depending on the needs of the customer.

Various of application

- Automatic stone edge polishing machines are used in a variety of applications, such as kitchen countertops, bathroom vanities, flooring tiles, and wall cladding. They are also used in the fabrication of monuments and sculptures.

Reduce material waste

- The use of automatic stone edge polishing machines has reduced the amount of waste generated during the stone processing and fabrication process. This is because the machine can be programmed to cut the stone slab to the exact size and shape required, reducing the amount of material that needs to be discarded.

Automatic stone edge polishing machines have transformed the stone industry by making the task of polishing stone slabs faster, safer, and more efficient. They have also enabled stone processing companies to produce high-quality products with consistent results, reducing costs and increasing customer satisfaction.

Machine Features

The grinding wheel of this automatic horizontal edge polishing machine adopts water-grinding piece and is equipped with snail buckle interface. The refueling is quick and convenient, the water mill removes dust, reduces dust pollution, and greatly improves the working environment. The motor can be intelligently oscillated. After the polishing wheel is worn out, the grinding wheel can be automatically compensated during the operation, saving time and improving efficiency. Roller assisted loading and unloading, the minimum processing size is 10-50mm*50mm. The automatic production mode adopted by the machine can meet the needs of customers for the production of stone wire type, and the finished products meet the national and export inspection standards. Adopting infinitely variable speed, the feeding speed and the amount can be adjusted during the working process. The maximum processing speed is 3m/min. The normal use of the machine is equivalent to 15 people working in normal stone processing, and the process defects caused by the workers are eliminated.

1. Increased Efficiency:

The automatic stone edge polishing machine is much faster than traditional hand polishing methods, which means that more stone slabs can be processed in less time.

2. Consistent Results:

The machine is computer-controlled, which means that the polishing heads move along the edges of the stone slab in a consistent pattern, resulting in a uniform finish.

3. Reduced Labor Costs:

The machine requires fewer operators than traditional hand polishing methods, which means that labor costs are reduced.

4. Improved Safety:

The machine is equipped with safety features that reduce the risk of accidents and injuries.

The automatic stone edge polishing machine has revolutionized the stone industry by making the task of polishing stone slabs faster, easier, and more efficient. With its increased efficiency, consistent results, reduced labor costs, and improved safety features, it is no wonder that more and more stone processing companies are adopting this technology.

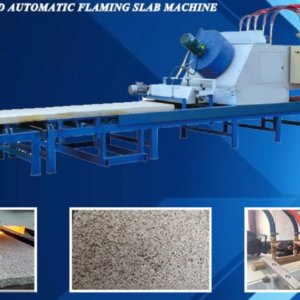

Machine Details Show

Automatic Horizontal Stone Edge Polishing Machine

Heads Distribution and Motor Details

Automatic Horizontal Edging Machine For Quartz

Marble Granite Automatic Stone Edging Machine

Automatic Stone Edging Machine

Automatic Stone Edge Polishing Machine

Backside of Polishing Disc

Frontside of Polishing Disc

Product made by automatic horizontal stone edging machine

Samples made by horizontal Stone Edge Profiling Machine

Machine Packing and Loading

Automatic Stone Edging Machine Packing and Loading

Machine Specifications

| Item Name | Unit | Value |

|---|---|---|

| NO. of Polishing Head | pc | 20 |

| Feed output speed | meter per minute | 1--23 |

| Minimun processing size | mm | 10-50 |

| Total power | kw | 22 |

| Machine weight | kg | 5000 |

| Machine dimensions | mm | 6100*1900*2000 |

| Working desk size | mm | 3050*1100*900 |