1. Introduction of stone digital laser templeter

2. What a Digital Templater Can Do for Stone Fabricators

3. Features of Stone Digital Templater

4. How to Operate a 2D/3D Stone Laser Templater

5. Why you need a stone digital laser templater system

6. Video Show

Introduction of stone digital laser templeter

In the ever-evolving world of stone fabrication, technological advancements continue to revolutionize the industry, making processes more precise, efficient, and streamlined. One such innovation is the Stone Digital Laser Templater—a cutting-edge tool that has transformed the way stone fabricators measure, template, and create accurate digital representations of stone surfaces. In this article, we will explore the capabilities and features of this remarkable device and delve into the steps involved in operating a 2D/3D stone laser templater.

What a Digital Templater Can Do for Stone Fabricators:

The advent of the digital laser templater has significantly enhanced the capabilities and productivity of stone fabricators. Gone are the days of relying solely on manual measuring and cutting techniques, which often led to inaccuracies, wasted materials, and increased labor time. The digital templater brings a multitude of benefits to the table, including:

1. Precision:

The stone digital laser templater utilizes laser technology to measure stone surfaces with unparalleled accuracy. It eliminates the potential for human error, ensuring precise measurements and minimizing the need for reworks or adjustments.

2. Efficiency:

By digitizing the templating process, fabricators can streamline their workflow, reducing the time required for measuring, templating, and designing. The digital templater allows for quick and efficient data collection, saving valuable time and resources.

3. Waste Reduction:

With precise measurements and a digital representation of the stone surface, fabricators can optimize material usage, reducing waste and optimizing cost-efficiency. This not only benefits the bottom line but also contributes to environmental sustainability.

4. Design Flexibility:

The digital templater enables fabricators to capture intricate details of stone surfaces, including curves, edges, and cutouts, with ease. This information can be transferred directly to design software, allowing for precise customization and intricate design work.

Features of Stone Digital Templater:

The Stone Digital Laser Templater is equipped with a range of powerful features that enhance its functionality and usability. Some notable features include:

1. Laser Measurement:

The templater utilizes advanced laser technology to capture highly accurate measurements of stone surfaces, even for complex shapes and contours.

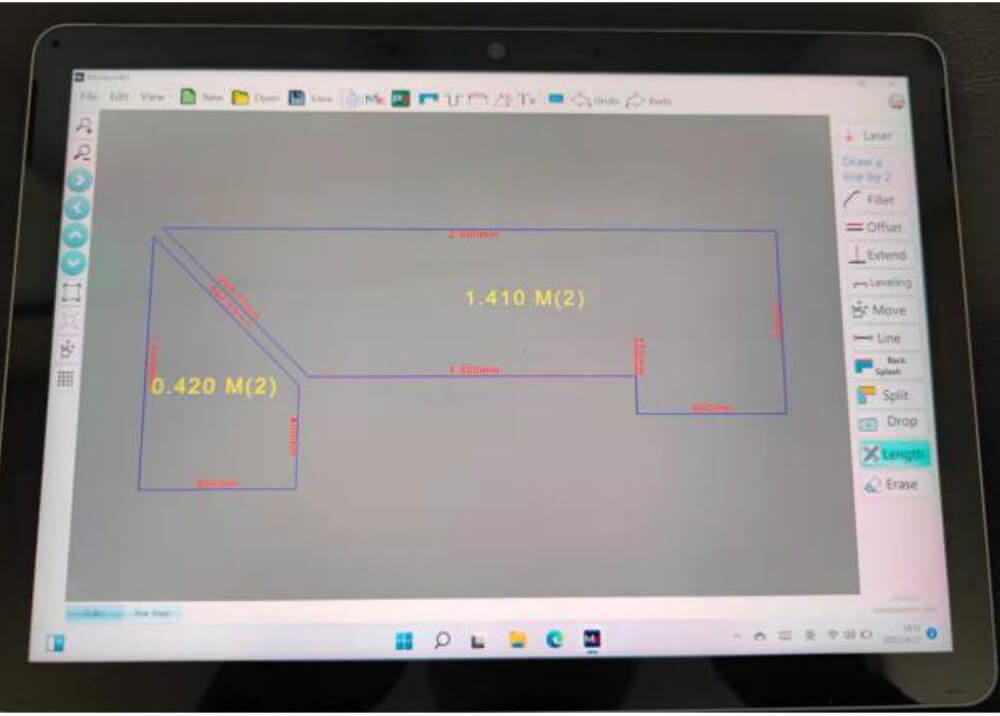

2. Touchscreen Interface:

The device features an intuitive touchscreen interface, allowing users to navigate through various functions, adjust settings, and visualize captured data in real-time.

3. Wireless Connectivity:

The digital templater seamlessly integrates with design software and other digital systems through wireless connectivity. This enables efficient data transfer and collaboration between different stages of the fabrication process.

4. 2D and 3D Templating:

The device supports both 2D and 3D templating, catering to different project requirements. Fabricators can easily switch between modes to capture surface measurements and generate detailed digital templates.

How to Operate a 2D/3D Stone Laser Templater:

Operating a 2D/3D stone laser templater involves the following steps:

1. Prepare the Templater:

Ensure the device is charged and powered on. Verify that the laser is calibrated correctly and adjust settings according to project requirements.

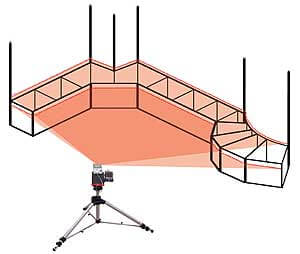

2. Position and Scan:

Place the templater on the stone surface and follow the on-screen instructions to initiate the scanning process. Move the device along the surface, capturing measurements as the laser scans.

3. Data Processing:

Once the scanning is complete, the captured measurements are processed within the templater. This data can then be transferred wirelessly to design software for further processing and customization.

4. Template Validation:

Review the digital template on the device’s touchscreen interface to ensure accuracy and make any necessary adjustments. This step allows fabricators to verify measurements and fine-tune the design before fabrication begins.

5. Export and Integration:

After validating the template, export the digital data to compatible

design software for seamless integration into the fabrication workflow. This enables precise cutting, shaping, and finishing of the stone material.

Why you need a stone digital laser templater system

1. Measurement Accuracy:

Stone digital laser templaters utilize advanced laser technology to capture measurements with exceptional precision. The lasers emit a beam that scans the stone surface, measuring the distances between the laser and the surface at multiple points. This data is then used to create a highly accurate digital representation of the stone’s shape and dimensions.

2. Time and Cost Savings:

Traditional manual templating methods can be time-consuming and prone to errors. Stone digital laser templaters significantly reduce the time required for measuring and templating, resulting in faster project turnaround times. Additionally, the precise measurements obtained by the templater help minimize material waste, optimizing cost-efficiency for stone fabricators.

3. Enhanced Design Capabilities:

The digital templater allows fabricators to capture intricate details of the stone surface, including curves, edges, and cutouts, with utmost accuracy. This level of detail enables designers and fabricators to create more intricate and customized stone pieces, catering to the unique requirements of each project.

4. Seamless Integration with Design Software:

Stone digital laser templaters are designed to integrate seamlessly with various design software programs used in the stone fabrication industry. The captured measurements and templates can be easily transferred to these software applications, where they can be further refined, customized, and used for precise fabrication instructions.

5. Portability and Ease of Use:

Stone digital laser templaters are designed to be portable and user-friendly. They are lightweight and compact, allowing fabricators to easily move them around the workshop or take them on-site for accurate measurements. The touchscreen interface and intuitive controls make operating the device straightforward, requiring minimal training or technical expertise.

6. Compatibility with CNC Machinery:

The digital templates created by the stone laser templater can be directly imported into computer numerical control (CNC) machinery. This compatibility allows fabricators to automate the cutting and shaping processes, ensuring precise replication of the design without the need for manual intervention.

7. Quality Assurance and Error Prevention:

The digital templater minimizes the potential for human error in the templating process. Fabricators can validate the digital template on the device’s touchscreen interface, ensuring accuracy and identifying any discrepancies before fabrication begins. This quality assurance step helps prevent costly mistakes and reworks down the line.

8. Documentation and Archiving:

Stone digital laser templaters offer the advantage of digital documentation and archiving. The captured measurements and templates can be stored digitally, creating a comprehensive database of past projects. This information can be easily accessed and reused for future reference, replication, or modification.

In summary, stone digital laser templaters provide stone fabricators with a range of benefits, including increased accuracy, time and cost savings, enhanced design capabilities, seamless integration with design software, portability, and error prevention. By embracing this technology, fabricators can elevate their craftsmanship, optimize their processes, and stay competitive in a rapidly evolving industry. The stone digital laser templater has emerged as an indispensable tool for modern stone fabricators, empowering them with unparalleled precision, efficiency, and design flexibility. By eliminating manual measurement errors and streamlining the templating process, this technology revolutionizes stone fabrication, resulting in superior quality products, reduced waste, and enhanced customer satisfaction. Embracing the capabilities of the stone digital laser templater paves the way for a more efficient and productive future in the stone fabrication industry.