1. Define of granite cutting bridge saw machine

2. Features of Granite Cutting Bridge Saw Machine:

3. Key Components of a Bridge Saw Machine

4. Bridge Saw Machine Operational Principles

5. Structure of granite bridge saw machine

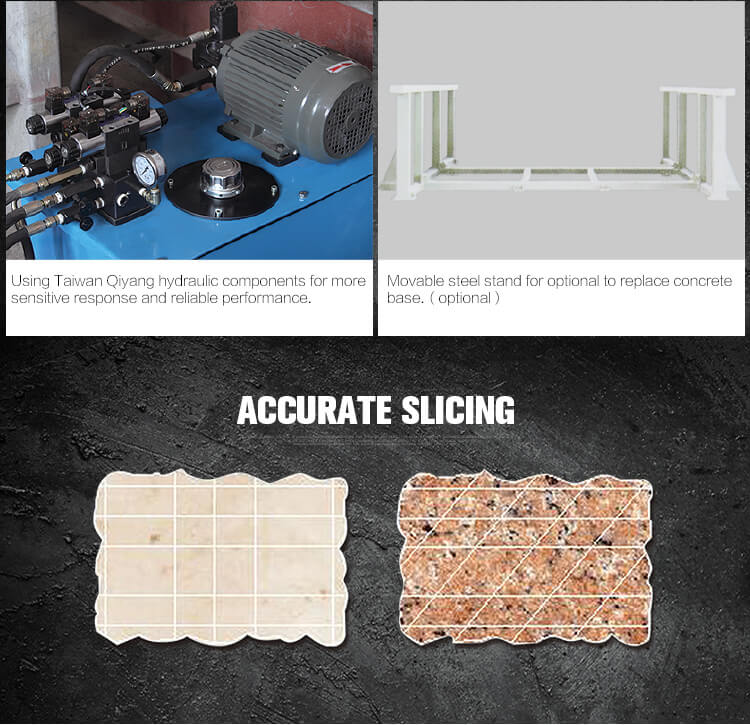

6. Details of Granite Bridge Saw Cutting Machine

7. Granite Bridge Saw Cutting Machine Specifications

8. Granite Bridge Saw Cutting Machine Video

Define of granite cutting bridge saw machine

Bridge saw machines have long been a vital tool in the stone industry, particularly for cutting granite slabs. These powerful machines have evolved over the years, with modern versions offering a range of features to streamline the cutting process and improve accuracy. This article will provide a comprehensive overview of bridge saw machines for granite cutting, exploring their key components, operational principles, advantages, and the latest technological advancements. A bridge saw machine is a large, industrial cutting machine designed for cutting large, heavy slabs of material, such as granite, marble, and other stones. The machine features a stationary worktable and a movable bridge that spans the length of the table. The bridge houses the cutting head, which moves along the X and Y axes, while the worktable may move along the Z-axis to adjust the height for different material thicknesses. This bridge saw machine is an ideal equipment for cutting granite two-dimensional stone slab with a certain size and shape. Before cutting, we need to set the blade position with a laser light. After setting operation parameters, the whole cutting process is automatic and programmed. Granite bridge saw machine is one of many types of stone cutting machine.Reliable Bridge saw machine for both granite and marble cutting.

Features of Granite Cutting Bridge Saw Machine:

Hydraulic Up and down:

Different with other bridge saw machine, the blade up and down of this machine is design with four hydraulic columns. This design promises a more powerful cutting and more accurate when machine is working.

Blade size:

Size of blade can be 600, 800 or customs by clients. Normally, we make 600mm blade with 20cm thickness max cutting.

Working Table:

Size of working table is L*W=3000*2000mm. Suitable for all customer cutting requirements. Table up 85 degree in vertical for slab load and unload, and also rotation in horizontal for 90 degree.

Jib Crane:

Customers can also order a slab crane as a part of this machine. Slab crane is a necessary for load slab onto machine table before cutting.

PLC Control:

PLC control system is used to input operation parameters on granite bridge saw machine (including cutting size and specification, moving speed, etc.) through human-machine interface, and the cutting process is automated and programmed.

Laser Light:

This machine used a infrared light to check the position of granite slab and cutting blade.

Cement Wall:

Compare with mono block bridge saw machine, this machine is a separated machine and it use cement wall or steel frame as the machine support.

Rotation Table:

Since it’s a separated granite bridge saw machine, machine table is installed separated also and the table is controlled by hydraulic system to do 90°rotation and 85 tilting

Diamond Saw Blade:

Bridge saw machine blade lifting is controlled by single cylinder hydraulic, double sliding plates and double dovetail guide structure.

Encoder:

There is a encoder or magnetic device installed on side beam of bridge saw machine to detect Longitudinal slice cutting

Precision:

These machines provide accurate, clean cuts, ensuring a high-quality finished product.

Efficiency:

Bridge saw machines can cut granite slabs quickly and with minimal waste, reducing material costs and increasing productivity.

Versatility:

With adjustable cutting depths and angles, bridge saw machines can produce a wide range of cuts, from simple straight cuts to intricate curved designs.

Automation:

Modern control systems allow operators to program complex cutting sequences, reducing manual labor and the potential for human error.

Key Components of a Bridge Saw Machine

1. Bridge:

The bridge is a rigid structure that spans the worktable, providing support for the cutting head and ensuring smooth, precise movements along the X and Y axes.

2. Cutting Head:

The cutting head houses the saw blade, which is typically a diamond-tipped circular blade designed for cutting through granite and other hard materials. The cutting head can be adjusted for different cutting depths and angles, offering versatility in the types of cuts produced.

3. Worktable:

The worktable is a large, flat surface where the granite slab is placed for cutting. It may feature clamps or other holding mechanisms to secure the slab in place and can move along the Z-axis to accommodate different material thicknesses.

4. Motor:

The motor powers the cutting head, providing the necessary force to rotate the saw blade at high speeds, ensuring efficient cutting.

5. Control System:

Modern bridge saw machines are equipped with advanced control systems that allow operators to program cutting sequences, adjust cutting parameters, and monitor the machine’s performance. This can include touchscreen interfaces, computer-aided design (CAD) software integration, and remote monitoring capabilities.

Bridge Saw Machine Operational Principles

The operation of a bridge saw machine for granite cutting involves the following steps:

1. The granite slab is placed on the worktable, and clamps or other holding mechanisms secure it in place.

2. The operator programs the desired cutting sequence and parameters into the control system, often using CAD software to create precise designs.

3. The cutting head moves along the X and Y axes, positioning the saw blade over the starting point of the cut.

4. The worktable raises along the Z-axis to bring the slab into contact with the saw blade.

5. The motor powers the saw blade, and the cutting head moves along the programmed path, cutting the granite slab with precision.

6. Once the cutting sequence is complete, the worktable lowers, and the cut pieces can be removed.

Structure of granite bridge saw machine

Bridge Structure

This saw machine is design with Bridge structure, a crossbeam is located on left and right side of longitudinal rails, with an independent work table.

Four Pillars

The cutting blade of bridge saw machine is installed in the main box, the main box is installed in the middle box, the middle box is connected with four guide pillars, the four guide pillars move up and down in the middle box through the hydraulic system, and the middle box is fixed on the crossbeam to move left and right. In the middle box, the middle box is connected with four guide pillars, which move up and down in the middle box through the hydraulic system, and the middle box is fixed on the crossbeam to move left and right.

Crossbeams

The left and right groups of gears installed on the crossbeam realize front and rear displacement of crossbeam through tooth row on two longitudinal rails

Hydraulic Worktable

The hydraulic worktable is installed separated from bridge saw machine which can rotate 90°or 360°and tilting 85°

Server Motor

Both left right travel of saw blade and front back travel of crossbeam are controlled by servo motor.

Details of Granite Bridge Saw Cutting Machine

Granite Bridge Saw Cutting Machine Specifications

| Item Name | Unit | Value |

|---|---|---|

| Blade Diameter | mm | 600 |

| Horizontal Travel | mm | 3200 |

| Longitudinal Travel | mm | 3200 |

| Vertical Travel | mm | 300 |

| Main Motor | KW | 18.5 |

| Total Power | KW | 21.5 |

| Size of table | mm | 3200*2000 |

| Table Rotation | n° | 90 |

| Machine overall | mm | 6000*5000*2800 |

| Weight | T | 5.6 |