Marble countertops epitomize luxury in modern kitchens and bathrooms, but achieving clean, precise cuts requires specialized tools and techniques. Whether you’re a fabricator, contractor, or DIY enthusiast, this comprehensive guide will walk you through cutting marble countertops like a pro—while highlighting essential machinery like stone cutting machines and stone diamond tools to streamline the process.

Why Precision Matters in Marble Cutting

Marble’s delicate veining and susceptibility to chipping demand meticulous handling. A single misaligned cut can ruin a slab worth thousands of dollars. Unlike granite, marble is softer (3–5 on the Mohs scale), making it prone to scratches and fractures if improper tools like standard grinding tools or generic blades are used.

Tools & Materials You’ll Need

1. Primary Cutting Tools

– Diamond-Blade Wet Saw: A cutting machine with a water-cooled diamond blade minimizes dust and prevents overheating.

– Angle Grinder: For curved cuts or adjustments, paired with a diamond segmented blade (part of stone diamond tools).

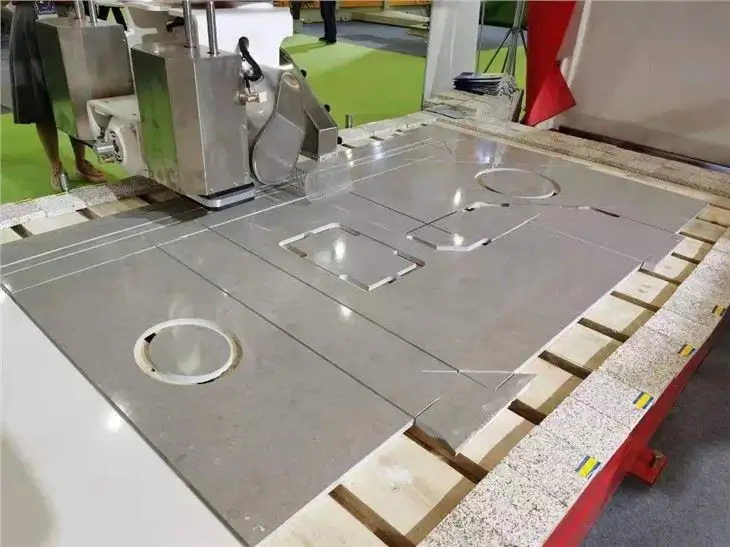

– CNC Router (Optional): For complex shapes, a CNC tool ensures robotic precision.

2. Measuring & Marking

– Laser measure or steel tape

– Grease pencil or painter’s tape

– Straightedge guide

3. Safety Gear

– N95 respirator

– Safety goggles

– Cut-resistant gloves

4. Post-Cutting Tools

– Stone polishing machine: To refine edges (e.g., bullnose, bevel).

– 220–3000 grit polishing pads (a type of polishing pads).

– Marble sealant

Step-by-Step Cutting Process

Step 1: Template Creation & Measurement

1. Use a cardboard or MDF template to replicate the countertop’s exact dimensions.

2. Transfer measurements to the marble slab using a grease pencil. Mark cut lines 1/8″ wider than needed to allow for polishing.

*Pro Tip: For sink or cooktop cutouts, drill starter holes at corners using a diamond core bit (a stone diamond tool essential).*

Step 2: Set Up Your Workspace

1. Place the slab on a stable, padded surface (foam insulation boards work well).

2. Position your stone cutting machine (wet saw) near a water source. Ensure the blade is designed for marble—look for segmented rims with a continuous diamond edge.

Step 3: Make the Cut

A. Straight Cuts with a Wet Saw

1. Align the marble slab with the saw’s guide fence.

2. Turn on the water pump to lubricate the blade.

3. Feed the slab slowly into the blade (1–2 inches per second). Let the tool do the work—forcing it increases chip risk.

*Critical Note: Never use a dry blade on marble. Heat buildup will crack the stone.*

B. Curved Cuts with an Angle Grinder

1. Attach a 4-inch diamond blade to the grinder.

2. Score along the marked line lightly, then deepen the cut gradually.

3. Use a stone polishing machine with polishing pads to smooth jagged edges post-cut.

Step 4: Edge Polishing

1. Start with 220-grit polishing pads to remove rough spots.

2. Progressively switch to finer grits (600 → 1500 → 3000).

3. Finish with a handheld stone polishing machine for a mirror-like edge.

Step 5: Seal & Protect

Apply a penetrating marble sealant to the cut edges to prevent staining.

Common Mistakes to Avoid

Mistake 1: Using Blunt Blades

A worn-out diamond blade on your stone cutting machine will chip edges. Replace blades after 15–20 hours of use.

Mistake 2: Skipping Water Cooling

Dry cutting generates heat, causing thermal shock. Always use a wet saw or mist system.

Mistake 3: Rushing the Polish

Skipping grit levels (e.g., jumping from 220 to 3000) leaves hazy finishes. Patient polishing with polishing pads is key.

When to Upgrade to Professional Machinery

While small projects can be handled with angle grinders, large-scale operations demand industrial tools:

– Stone Bridge Saw Machine: Ideal for cutting thick slabs (3cm+) with laser-guided accuracy.

– CNC Tools: Programmable for intricate inlays or waterfall edges.

– Stone Polishing Machine: Saves hours on edge finishing vs. manual methods.

Cost Comparison: DIY vs. Professional Fabrication

| Task | DIY (Time/Cost) | Professional Tools (Time/Cost) |

|———————|————————–|———————————-|

| Straight Cut | 2 hours, $50 (blade) | 20 mins, $5 (via stone cutting machine) |

| Edge Polishing | 3 hours, $30 (pads) | 45 mins, $10 (stone polishing machine) |

| Complex Cutout | High risk of errors | Flawless with CNC tools |

FAQs About Cutting Marble

Q: Can I use a regular circular saw?

A: Only with a diamond blade and water attachment. However, a dedicated stone cutting machine offers better stability.

Q: How do I prevent “vein blowout”?

A: Reinforce fragile veins with epoxy resin before cutting and use low-vibration tools like stone bridge saw machines.

Q: Why does my blade wander during cuts?

A: Dull blades or improper feed speed. Ensure your stone diamond tools are sharp and maintain steady pressure.

Why Invest in Quality Stone Machinery?

At MosCut, we provide:

– Stone Cutting Machines: Engineered for marble’s unique properties.

– Stone Diamond Tools: Long-lasting blades and polishing pads for flawless finishes.

– CNC Tools: For architects pushing design boundaries.

These tools aren’t just purchases—they’re investments in precision, efficiency, and client satisfaction.