Bridge Saw Machines

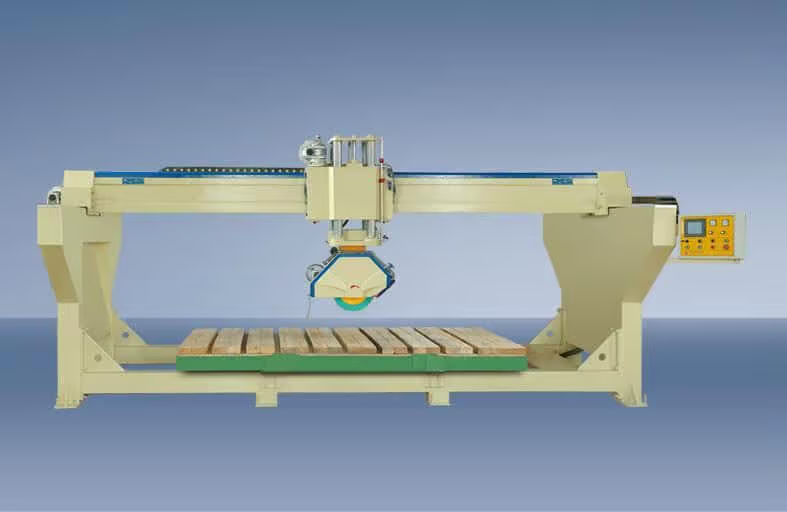

- 1

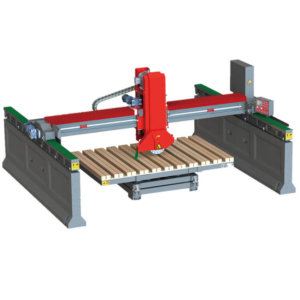

- 2

The stone fabrication industry has long been the backbone of architectural and decorative advancements, providing the necessary tools and machinery to transform raw, natural materials into stunning pieces of work. At the heart of this industry is a pivotal piece of equipment known as the bridge saw machine. This article aims to elucidate the intricacies of the bridge saw machine, exploring its definition, capabilities, and the diverse range of materials it can proficiently cut.

What is a Bridge Saw Machine?

A bridge saw machine is a robust piece of industrial equipment used in the cutting of natural stone slabs and other robust materials. It derives its name from its structural design, which features a bridge-like overhead beam that supports a suspended cutting tool. This tool, typically a diamond blade, moves along the bridge, allowing for precise and straight cuts through hard stone materials.

The engineering behind the bridge saw machine enables it to offer consistent performance and high precision in cutting. The machine is typically constructed from heavy-duty materials to withstand the rigors of cutting through tough stone. It can be either manually operated or CNC (Computer Numerical Control) automated, with the latter providing exceptional accuracy through computerized control.

What Can a Bridge Saw Machine Do?

The versatility of a bridge saw machine is one of its most remarkable features. It is designed to handle a variety of stone materials, making it an indispensable tool for stonemasons and fabricators. Below are some of the materials that a bridge saw can cut:

Marble: Known for its delicate beauty and used in high-end applications, marble can be precisely cut with a bridge saw machine to create stunning countertops, flooring, and artistic sculptures.

Granite: Due to its hardness and grainy structure, granite requires a robust cutting tool. A bridge saw machine can slice through granite slabs with ease, making it ideal for creating durable kitchen countertops and outdoor applications.

Mosaic: Mosaic involves assembling small pieces of colored stone or glass to create patterns or images. A bridge saw can cut larger pieces down to size for detailed mosaic work.

Terrazzo Tile: Composed of chips of marble or granite set in concrete and polished to produce a smooth surface, terrazzo tiles require precise cutting which can be achieved by a bridge saw machine for a perfect fit in flooring installations.

Quartz: Engineered quartz is a composite material used for countertops and other surfaces. A bridge saw machine can cut through quartz slabs, allowing for custom shapes and sizes to match design specifications.

The ability of the bridge saw machine to work with such a diverse range of materials makes it an essential tool in the stone industry. Its precision cutting abilities ensure that each piece of stone is perfectly shaped and sized for its intended application, whether it be for structural purposes or decorative finishes.

In addition to straight cuts, modern bridge saw machines equipped with advanced features can also perform beveled and miter cuts, enabling them to create complex edge profiles. This functionality expands the creative possibilities for stone fabricators, allowing them to cater to bespoke designs and intricate architectural details.

Bridge saw machine is more than just a piece of machinery; it is the lifeblood of the stone fabrication industry. Its ability to cut through various stone materials with precision and efficiency makes it an invaluable asset for those looking to transform raw stone into works of art. Whether it’s shaping marble for a grand staircase or slicing granite for a kitchen countertop, the bridge saw machine stands as a testament to human ingenuity in harnessing the beauty of natural stone.

Diverse Dimensions of Bridge Saw Machines

The categorization of bridge saw machines can be as nuanced and varied as the projects they are used for. The sophistication of these machines has evolved to meet the specific demands of the stone industry. To understand the range and capabilities of bridge saw machines, we can classify them based on several dimensions, such as the material they are designed to cut, the size of the stone they can handle, their cutting method, and the level of automation they offer.

Categorization by Material

Marble Bridge Saw: These saws are specifically calibrated to cut through marble, a softer stone, with precision without causing cracks or damage to the delicate material.

Granite Bridge Saw: Equipped with more robust blades and motors to handle the hardness of granite, these saws are designed for durability and power.

Quartz Bridge Saw: These machines are tailored for cutting engineered quartz with accuracy, catering to the growing popularity of quartz in modern design.

Classification by Stone Size

Bridge Saw for Stone Slabs: These saws are built to handle large, flat pieces of stone and are commonly used in fabricating countertops and large tiles.

Bridge Saw for Blocks: These machines are designed to slice through massive blocks of stone, segmenting them into more manageable slabs before further refinement and shaping.

Sorting by Cutting Method

Straight Cutting Machine: As the name suggests, this machine is optimized for making straight cuts and is a staple in most stone workshops.

Angle Chamfering Machine: This variant allows for beveled cuts, adding chamfers to edges of stone pieces for a finished look.

CNC Cutting Machine: These are highly precise and versatile machines that can perform complex cuts and intricate shapes, controlled by computer numerical programming.

Segmentation by Machine Automation

Regular Bridge Saw Machine: This is a more manual option that requires operator skill but is also more affordable.

3-Axis Bridge Saw: This machine offers movement in three dimensions (X, Y, and Z), allowing for more complex cuts than a regular bridge saw.

4-Axis Bridge Saw: Adding another degree of freedom, these machines can rotate the cutting head or the table for even more complex shapes and profiles.

CNC 5-Axis Bridge Saw: The pinnacle of bridge saw technology, these machines offer the greatest versatility and precision. They can execute intricate three-dimensional cutting paths for sculptural work or complex joinery.

Additional Considerations in Classification

Beyond these primary categories, bridge saw machines can also be differentiated by other aspects such as:

Portability: Some bridge saws are designed to be portable for on-site work, while others are stationary and intended for industrial settings.

Cooling System: Different cooling systems may be employed to manage heat generated during cutting, such as water-cooled versus air-cooled systems.

Interchangeable Heads: Some machines offer interchangeable heads for different types of cuts or materials, increasing their versatility.

Power Source: Electric versus hydraulic power can also be a distinguishing factor, affecting the machine’s performance and maintenance requirements.

The sorting of bridge saw machines is multifaceted and reflects the diverse needs of the stone cutting industry. From the material they cut to their automation level, each type of bridge saw machine serves a specific purpose, enabling craftsmen and manufacturers to achieve precision and efficiency in their work with stone.

Applications of Bridge Saw Machines

Bridge saw machines are indispensable in various sectors where precision stone cutting is paramount. The following are some of the primary applications of bridge saw machines in different industries:

Countertop Fabrication

One of the most common uses of bridge saw machines is in the fabrication of stone countertops for kitchens and bathrooms. These machines can make precise cuts to ensure that countertops fit the designated space perfectly and accommodate fixtures such as sinks and cooktops.

Architectural Elements

Bridge saws are used to cut stone for a variety of architectural elements, including window sills, door frames, and facades. The ability to produce straight and angled cuts makes them ideal for creating the specific shapes and sizes needed in building construction.

Flooring and Tiles

The precise cutting capabilities of bridge saw machines allow for the production of uniform and bespoke tiles used in flooring. This includes cutting large slabs into smaller, more manageable tiles or creating custom-sized pieces for unique floor designs.

Monument and Tombstone Creation

The stone-cutting precision that bridge saw machines offer is essential in the monument-making industry, where they are used to cut slabs of marble, granite, or other stone materials into tombstones and memorials with exact dimensions.

Sculpture and Artistic Carvings

Artists and sculptors use bridge saw machines to rough out large blocks of stone before refining them into intricate sculptures. The machine’s initial cuts are crucial to defining the basic shape of the artwork.

Furniture Making

Bridge saws are also utilized in crafting stone furniture pieces, such as tabletops, benches, and decorative elements. They can cut and shape stone to fit specific designs and dimensions required for high-end, durable furniture.

Paving Stones and Garden Features

For outdoor landscaping, bridge saw machines cut natural stone into pavers, stepping stones, and other garden features. These machines can produce consistent and uniform cuts, which are essential for creating aesthetically pleasing and functional outdoor spaces.

Water Jet Cutting Integration

Some bridge saw machines are equipped with or work in tandem with water jet cutting technology, allowing for even more intricate designs and the ability to cut through a wider range of materials, including metal and glass, expanding their applications beyond stone cutting.

Versatility of bridge saw machines makes them an essential tool across various industries where precision stone cutting is required. Their applications extend from the functional aspects of construction to the artistic endeavors of sculpture, demonstrating their critical role in both industrial and creative settings.

Features of Bridge Saw Machines

Bridge saw machines are equipped with a range of features that enhance their functionality, efficiency, and ease of use. Understanding these features is crucial for anyone involved in the stone industry, as they directly impact the machine’s performance and the quality of the final product. Here are some key features commonly found in bridge saw machines:

Robust Construction

Bridge saw machines are built with heavy-duty materials that provide stability and durability, allowing them to withstand the stress of cutting through hard stone materials. The construction typically includes a rigid frame that reduces vibrations during cutting, which is essential for achieving precise cuts.

Precision Cutting

High precision is a hallmark of bridge saw machines, with many models featuring laser alignment systems that help in guiding the cuts accurately. The precision of these machines ensures that each piece of stone is cut to exact specifications, minimizing material waste and ensuring a high-quality finish.

Adjustable Cutting Head

Many bridge saws come with a cutting head that can be tilted and adjusted to make miter cuts in addition to straight cuts. This feature is particularly important when fabricating countertops with beveled edges or when joining two slabs at an angle.

Motorized Movement

The cutting head of a bridge saw machine is typically motorized, allowing for smooth and controlled movement along the bridge. This can be manual, semi-automatic, or fully automatic, depending on the machine’s design and level of sophistication.

Programmable Cut Plans

Advanced bridge saw machines feature CNC technology that allows operators to input detailed cut plans into the machine’s computer. This capability enables the machine to execute complex cutting sequences automatically, with minimal human intervention.

Water Cooling System

To prevent overheating and reduce dust during the cutting process, bridge saw machines are equipped with water cooling systems. The water also helps to prolong the life of the diamond blades by reducing friction and wear.

User-Friendly Controls

Modern bridge saw machines offer user-friendly interfaces that simplify operation. Touchscreen panels, easily accessible control buttons, and pre-programmed settings help operators manage cutting processes with greater ease and efficiency.

Safety Features

Safety is paramount when operating heavy machinery. Bridge saws are designed with various safety features such as emergency stop buttons, protective covers over the cutting blade, and interlocking systems that prevent the machine from operating when maintenance doors are open.

Compatibility with Various Blade Sizes

To accommodate different types of cuts and materials, bridge saw machines can often be fitted with a range of diamond blade sizes. This versatility allows operators to select the most appropriate blade for the material at hand, from dense granite to delicate marble.

Each feature of a bridge saw machine contributes to its overall performance and suitability for specific tasks within the stone industry. When selecting a bridge saw, it’s important to consider which features align with your particular cutting needs and operational workflow.

Why You Should Purchase Your Bridge Saw from Us

When it comes to investing in a bridge saw machine, selecting the right provider is as crucial as the equipment itself. Our commitment to excellence in both product quality and customer service sets us apart in the industry. Here are compelling reasons why purchasing a bridge saw from us is a decision that will benefit your business:

Superior Quality and Craftsmanship

Our bridge saw machines are engineered with precision and built to last. We use only the highest grade materials and components, ensuring that each machine we sell is robust, reliable, and capable of withstanding the rigors of heavy use in demanding environments.

Cutting-Edge Technology

We stay at the forefront of technological advancements in the stone cutting industry. Our machines incorporate the latest innovations, including advanced CNC control systems, laser guide technology, and efficient water cooling systems, to ensure you are receiving top-of-the-line equipment.

Customization Options

We understand that each stone fabrication business has unique needs. That’s why we offer customizable bridge saw solutions. Whether you need a machine with specific dimensions, power requirements, or additional features, we can tailor our machines to your specifications.

Exceptional After-Sales Support

Our relationship with clients doesn’t end at the sale. We provide comprehensive after-sales support, including installation assistance, operator training, maintenance services, and readily available spare parts to minimize any potential downtime.

Industry-Leading Warranty

We stand behind our products with an industry-leading warranty that covers defects in materials and workmanship. This warranty reflects our confidence in the durability and performance of our bridge saw machines and provides you with peace of mind.

Competitive Pricing

While we do not compromise on quality, we strive to offer our bridge saw machines at competitive prices. We believe in providing value to our customers, ensuring that you receive an excellent return on investment when you choose to do business with us.

Expert Consultation

Our team comprises industry veterans who are available to provide expert consultation on machine selection and operation. We help you identify the most suitable bridge saw for your specific needs and ensure that you’re making an informed decision.

Proven Track Record

Our track record speaks for itself. With numerous satisfied customers and a portfolio of successful installations, our reputation in the stone cutting industry is solid. We take pride in the trust that clients place in us and work tirelessly to uphold and build upon that trust.

Purchasing your bridge saw from us means investing in a partnership that values quality, innovation, and customer satisfaction above all else. Let us help you elevate your stone fabrication capabilities with a machine that promises performance, precision, and profitability.

How to Purchase a Bridge Saw Machine

Acquiring a bridge saw machine is a significant investment for any stone fabrication business. To ensure you make an informed purchase that aligns with your specific needs and budget, follow these steps:

1. Assess Your Requirements

Start by evaluating the needs of your business. Consider the types of materials you will be cutting, the sizes of the stone, and the complexity of the cuts you need to make. Determine whether you require a machine with basic functionality or one with advanced features such as CNC capabilities or custom cutting options.

2. Set Your Budget

Decide on a budget for your bridge saw machine. Keep in mind that while higher-end models may offer more features and durability, there are also reliable options available at various price points that can suit smaller budgets without compromising on essential functions.

3. Research Suppliers

Look for reputable suppliers who specialize in bridge saw machines. Check their product range, read customer reviews, and compare the specifications of different models. Look for suppliers that offer strong after-sales support and warranties.

4. Request Quotes and Demonstrations

Contact suppliers to request quotes for the machines that meet your criteria. Ask if they offer live demonstrations or virtual tours of their equipment in action. Seeing a machine operate can give you a better understanding of its performance and ease of use.

5. Inquire About Customization

If you have specific requirements, discuss customization options with the suppliers. Some may be able to modify existing models or provide bespoke solutions tailored to your business’s needs.

6. Consider Financing Options

If purchasing a machine outright is not feasible, inquire about financing options. Many suppliers offer leasing arrangements or payment plans that can make the acquisition more affordable.

7. Evaluate Technical Support and Training

A good supplier should offer comprehensive technical support and training for your staff. Ensure that they provide adequate resources to help you get the most out of your new machine.

8. Check Delivery and Installation Services

Confirm the logistics of delivery and installation. Reliable suppliers will ensure that the machine is delivered safely and installed correctly, providing guidance on proper setup and operation.

9. Review the Contract and Warranty

Before making a purchase, carefully review the sales contract and warranty details. Make sure you understand the terms of service, warranty coverage, and any guarantees on parts and labor.

10. Make Your Purchase

Once you are satisfied with all aspects of the deal, proceed with the purchase. Ensure you receive all necessary documentation, including user manuals, maintenance guides, and warranty papers.

By following these steps, you can make a confident decision when investing in a bridge saw machine that will serve as a valuable asset to your business for years to come.

Maintenance of Bridge Saw Machines

Proper maintenance is crucial to extend the lifespan of your bridge saw machine, ensure its operational efficiency, and maintain the precision of cuts. Here is an essential point to consider for maintaining your bridge saw machine:

Regular Cleaning and Lubrication

One of the most fundamental aspects of maintenance is keeping the machine clean and well-lubricated. Stone dust and debris can accumulate on the machine’s components, leading to increased wear and tear. It’s vital to follow a regular cleaning schedule to remove any buildup from the bridge, rails, and worktable. Additionally, lubricate all moving parts according to the manufacturer’s recommendations to ensure smooth operation and prevent rust or corrosion.

Inspect and Replace Wear Parts

Over time, certain parts of the bridge saw machine will experience wear and may need replacement. Regularly inspect components such as the saw blade, belts, bearings, and guide rails for signs of wear or damage. Replacing these parts before they fail can prevent more extensive damage to the machine and avoid costly downtime.

Monitor Water Cooling System

The water cooling system plays a critical role in preventing blade overheating and reducing dust during cutting. Ensure that the water pump is functioning correctly and that there is a consistent flow of water to the blade during operation. Check for any clogs or leaks in the system and address them promptly.

Calibrate and Align Components

To maintain cutting accuracy, it’s important to periodically calibrate and align the bridge saw components. This includes checking the alignment of the saw blade to the cutting table and ensuring that the laser guide (if equipped) is accurately marking the cut line. Misalignment can lead to imprecise cuts and uneven wear on the blade.

Check Electrical Systems

Electrical issues can lead to malfunctions or safety hazards. Regularly inspect the bridge saw’s electrical connections, wires, and control panels for any signs of damage or wear. Ensure that all safety switches and emergency stops are functioning correctly.

Follow Manufacturer’s Maintenance Schedule

Each bridge saw machine will have a manufacturer-recommended maintenance schedule based on operational hours or time intervals. Adhere to this schedule for tasks such as changing hydraulic fluids, inspecting motors, and servicing gearboxes.

Train Operators on Proper Use

Proper training for operators is essential for maintaining a bridge saw machine. Operators should be knowledgeable about best practices for using the machine, understanding its limitations, and recognizing when maintenance is needed.

Keep Maintenance Records

Maintain detailed records of all maintenance activities, including dates, services performed, parts replaced, and any repairs conducted. This documentation can help in diagnosing future issues and planning preventive maintenance.

By focusing on regular maintenance, you can ensure that your bridge saw machine continues to operate at peak performance, providing precise cuts and reliable service for your stone fabrication needs.