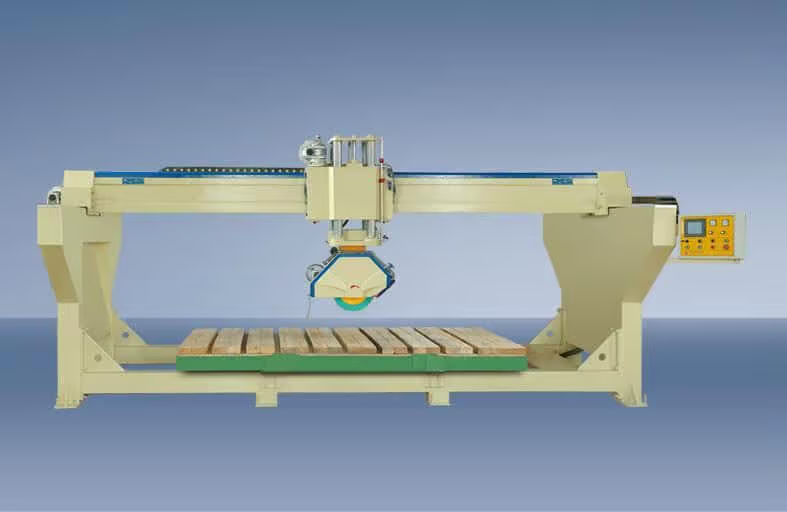

What a Stone Cutting Machine Can Do

In the realm of construction and sculpture, the stone cutting machine stands as a testament to human ingenuity and our ability to shape the natural world to our needs. These machines, which range from handheld tools to industrial-sized equipment, have revolutionized the way we work with one of the most fundamental building materials known to man. In this article, we will delve into the intricacies of stone cutting machines, exploring their capabilities and the vast array of materials they can transform.

Stone cutting machines are pivotal tools in the manipulation of natural stone, offering precision and versatility that manual techniques cannot match. Whether it’s shaping a slab of granite for a kitchen countertop or carving a delicate marble statue, these machines facilitate the creation of enduring works of art and sturdy architectural elements. As technology advances, we can only expect these machines to become even more sophisticated, further expanding the possibilities within the realm of stone crafting.

One of the most remarkable aspects of stone cutting machines is their versatility. These machines are not limited to a single type of stone but can handle a diverse range—from soft and sedimentary to hard and igneous varieties.

The ability to cut these different types of stone materials opens up endless possibilities in construction, architecture, and art. From intricate inlays and detailed mosaics to robust architectural components and delicate sculptures, stone cutting machines empower craftsmen and builders to push the boundaries of design and functionality.

Marble

Known for its elegance and beauty, marble is a favorite among sculptors and builders. Stone cutting machines can navigate the delicate nature of marble, providing smooth cuts that highlight its natural veining.

Granite

Renowned for its hardness and durability, granite presents a challenge that stone cutting machines can meet with ease. The precision cutting ability of these machines ensures that granite's toughness is no impediment to shaping and sizing for countertops, tiles, and other applications.

Limestone

Often used in building materials and industrial processes, limestone can be effectively cut by stone cutting machines for use in construction as well as in the creation of decorative elements.

Sandstone

The abrasive nature of sandstone requires a robust cutting solution. Stone cutting machines offer the necessary power to cleanly cut through this material, which is often used in building facades and as paving material.

Quartz

Engineered quartz has become increasingly popular for its durability and the variety of colors available. Stone cutting machines are adept at shaping quartz slabs for use in kitchen and bathroom surfaces.