1. Introduce of 5 Axis Bridge Saw

2. Features of 5 Axis Bridge Saw

3. Functions 5 Axis Bridge Saw

4. Applications of 5 Axis Bridge Saw

5. What are some factors to consider when choosing a 5 axis bridge saw machine?

6. Spare part list of 5 Axis Bridge Saw

7. 5 Axis Bridge Saw Specifications

8. Details of 5 Axis Bridge Saw

9. Products Made By 5 Axis Bridge Saw

10. Machine Packing and Loading

11. Customer Cases

12. Machine Working Video

Introduce of 5 Axis Bridge Saw

Ordinary bridge saw machine is mainly used in stone industry, and the mainly function for common bridge saw is cutting marble and granite. It has been used for many years. Bridge saw is one of the most important machines in stone processing plant. The biggest advantage of regular bridge saw machine is that the equipment has a strong cutting ability, it can cut various sizes of stone slabs with fast cutting speed and precision cutting. The working efficiency of regular bridge saw machine is much higher than manual stone cutting machine. In recent years, stone manufacturers are basically equipped with this kind of machine, which makes the cutting machinery industry more and more powerful. The above introduction is the advantage of common bridge cutting machine in stone cutting, but it is still a little insufficient for the processing of stone counter top. There are many processing steps for the stone counter top. Cutting is only one part of it. For example, cutting the edge at 45 ℃ and drilling, polishing and grinding are not available on regular bridge saw, and ordinary stone bridge cutting machine can not complete the whole process. In order to achieve the whole process in one step, the 5 axis bridge saw machine is used to complete all the processes at one time. The products can meet all the needs of customers without secondary processing. It can save labor cost, reduce power consumption, improve efficiency and enhance profitability.

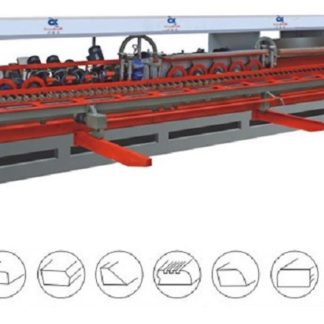

5 axis bridge saw machine is a kind of automatic CNC machining equipment which moscut creates for the majority of stone processing enterprises in order to meet the diversified processing needs of the stone market. Its processing functions include: arbitrary shape line, arc edge, duckbill edge, straight edge, bevel edge, anti slide groove, dry hanging slotting, hand washing table processing and shaped edge forming. 5 Axis Bridge Saw Machine has many processing functions, one machine multi-purpose, small occupation, simple operation, accurate processing, fast and convenient conversion of different functions

Features of 5 Axis Bridge Saw

Easy to learn CAD / CAM software, any angle, any position, any graphics

- Simple and intuitive, what you see is what you get

- Straight line, arc, grid and line are all available

- Grooving, edge grinding, beveling and chamfering can be cut done on this 5 axis bridge saw machine

- Roman style, hemp style, flowerpot and heteromorphism can be easily processed

- Curved surface, carving, hole opening, profiling processing

- Seamless docking scanner, typesetting on demand, saving material and time

- Easy to use, intelligent and convenient

- Imported CNC control system and imported servo motor drive are adoptedon this 5 axis bridge saw machine

- colorful touch screen, USB, Ethernet interface connection

- It can connect with the scanner seamlessly to realize real-time scanning and typesetting;

- It has the function of remote diagnosis through Internet, and the parameters of CNC system can also be modified by the computer connected with remote diagnosis.

Once positioning, all processes are completed at one time, and the accuracy and speed are guaranteed. Different saw edge, no matter what angle, can achieve five axis multi-directional edge cutting and edge grinding.

Automatic tool change spindle can realize synchronous processing and engraving. The supporting tools include saw blade, milling cutter, forming wheel and polishing wheel. The cutting, chamfering and polishing functions can be completed at one time without repeated positioning, so as to improve the machining accuracy, enhance the processing quality and work efficiency.

Functions 5 Axis Bridge Saw

Automatic five axis bridge saw machine, multi language conversion, x-y-z-a-b five axis linkage, more widely used, suitable for granite, marble large plate, artificial stone, rock plate and other kinds of stone, can achieve cutting, chamfering, edge grinding, slotting, drilling, circular arc and other abnormal processing, simple operation and stronger practicability. Below are functions of 5 axis bridge saw machine: The machine head can rotation 360 degrees freely, and can cut the stone slab at any angle and shape: transverse cutting, longitudinal cutting, arc cutting, ellipse cutting and circular cutting. The machine can also be used for concave convex edge grinding. In addition to cutting modeling, it can also be used for large slab cutting, 45 degree chamfering, pot hole, stove hole, oblique line cutting. The worktable is turned over at 85 degrees, which makes loading and unloading convenient and labor-saving. There is no need for complex operation, just input data on the control system. There is a grinding wheel device, which can grind and polish the table face and cutting surface.

Applications of 5 Axis Bridge Saw

5 axis bridge saw machines are widely used in the stone fabrication industry for a variety of applications. Here are some common applications of 5 axis bridge saw machines:

1. Countertops and vanity tops:

5 axis bridge saw machines are commonly used to cut and shape stone slabs into countertops and vanity tops for kitchens and bathrooms. They can create complex shapes and designs, including curved edges and sink cutouts.

2. Architectural elements:

5 axis bridge saw machines can be used to create a range of architectural elements, such as fireplace surrounds, columns, and arches. They can easily create intricate designs and shapes for a variety of decorative and functional applications.

3. Flooring and wall cladding:

5 axis bridge saw machines are commonly used to cut stone materials into tiles for flooring and wall cladding. They can create different sizes and shapes of tiles, and can also create custom designs and patterns.

4. Sculptures and monuments:

5 axis bridge saw machines can be used to create sculptures and monuments out of stone materials. They can create complex shapes and designs that require high precision and accuracy.

5. Stone Furniture:

5 axis bridge saw machines can be used to create furniture pieces out of stone materials, such as tables, benches, and decorative pieces. They can create unique designs and shapes that are not possible with other materials.

Overall, 5 axis bridge saw machines are a versatile tool that can be used in a wide range of stone fabrication applications. Their advanced features and capabilities make them a popular choice for stone processing operations that require high precision and accuracy in their cutting tasks.

What are some factors to consider when choosing a 5 axis bridge saw machine?

There are several factors to consider when choosing a 5 axis bridge saw machine for your stone processing operation. Here are some key factors to keep in mind:

1. Size and capacity:

The size and capacity of the machine will determine the maximum size of stone materials that can be processed. Consider the size and weight of the largest materials you’ll be working with, and choose a machine that can handle them.

2. Cutting capabilities:

Consider the types of cuts and shapes you need to make for your specific application. Some machines may be better suited for straight cuts, while others may be more versatile and able to perform complex shapes and designs.

3. Automation and features:

Look for machines with advanced features such as automatic tool changing, touch screen interfaces, and computerized control systems. These features can improve efficiency and productivity in stone processing operations.

4. Maintenance and support:

Consider the maintenance requirements of the machine and the level of support provided by the manufacturer. Look for machines with easy-to-replace parts and a reliable support system in case of any issues.

5. Cost:

5 axis bridge saw machines can vary in price depending on their size, features, and capabilities. Consider your budget and the long-term return on investment when choosing a machine.

6. Brand reputation:

Consider the reputation of the manufacturer and the quality of their products. Look for machines from established brands with a track record of producing high-quality and reliable equipment.

7. Safety:

Safety is a top priority in any stone processing operation. Look for machines with safety features such as emergency stop buttons, protective covers, and sensors that detect any anomalies or malfunctions.

Choosing the right 5 axis bridge saw machine for your stone processing operation requires careful consideration of your specific needs and requirements. By considering these key factors, you can select a machine that will provide the precision, efficiency, and reliability needed for your operation.

Spare part list of 5 Axis Bridge Saw

The major spare parts of a 5 axis CNC bridge saw machine are:

1. Guide rails and bearings:

To provide smooth multi-axial movement to the cutting head.

2. Drive motors:

Hydraulic drive motors to power different axes of cutting head.

3. Hydraulic pumps:

Used to generate and pump the hydraulic fluid needed to generate force and action.

4. Hydraulic cylinders:

Installed on all 5 axes to provide linear movement.

5. Hydraulic valves:

Control the flow and direction of the hydraulic fluid to the cylinders according to the automation program.

6. Diamond cutting blades:

Different types of diamond blades needed for a range of cutting applications. They need to be replaced when worn out.

7. Control panel components:

Key parts like servo drives, programmable logic controllers, motion controllers etc. to control the CNC automation.

8. Conveyor rollers and bearings:

Enable the to and fro movement of stone slabs on the conveyors. They need replacing when damaged.

9. Safety components:

Components like sensors, switches, braking systems, etc. to monitor safe operation of the machine.

10. Structural parts:

Base plates, beams, spindle supports, stands etc. provide structural framework to the machine.

5 Axis Bridge Saw Specifications

| Programming method 1 | CAD& Manual | CAD& Manual |

|---|---|---|

| Control method | CNC | CNC |

| Main motor power | 4kw 380V | 4kw 380V |

| R.P.M | 3000r/min | 3000r/min |

| Blade size | 350mm | 350mm |

| X-axis working stroke | 3000mm | 3500mm |

| Y-axis working stroke | 2000mm | 2000mm |

| Z-axis working stroke | 260mm | 260mm |

| A-axis working stroke | 360°free rotation | 360°free rotation |

| B-axis working stroke | Auto 0-90 degree chamfer | Auto 0-90 degree chamfer |

| Cutting thickness | 70mm | 70mm |

| Working table size | 3000*2000mm | 3500*2000mm |

| Overall size | 4500*2750*2100mm | 5000*2750*2100mm |

| Weight | 2100KG | 2200KG |

| 20’container load | 1 | 1 |

Details of 5 Axis Bridge Saw

Products Made By 5 Axis Bridge Saw

Machine Packing and Loading

Customer Cases