1. Introduct of Bridge Saw

2. Features of Bridge Saw For Sale

3. Automation and Technology

4. Bridge Saw Machine Details

5. Machine Loading And Packing

6. Bridge Saw Machine For Sale Specifications

7. Bridge Saw Working Videos

Introduct of Bridge Saw

Bridge Saw is special machine for slab cutting, it includes bridge part/main machine, two pieces of side beams,rotation table and hydraulic part. It’s a basic machine for stone cutting. The electric panel and main motor are set on the main machine part. Bridge saw machine adopts a 18.5 KW spindle motor, it means the saw blade is drive by motor directly and it didn’t transfer by belt, that is very powerful. With this powerful motor, bridge saw machine can easily cut any kinds of stone even hard granite materials. Conveyor moving speed is controlled by inverter, so you can set this Bridge saw speed according to the different hardness of stone. Also each head go up/down , moving on the beam is by motor.

Features of Bridge Saw For Sale

On bridge saw Machine, there are several sensors installed on the machine.This is similar design with arc slab polishing machine. It can control blade left and right moving and up and down moving. The two pieces of side beams on bridge saw are design with screw guide,this is a very useful design for bridge part moving forward and back.Also the screw guide devices are very stable after long time working. On the bridge part of machine, we can also find a electric panel,all important electric components are set inside this panel includes inverter, PLC and other ones. The PLC set is connect with the computer screen of stone saw machine, these two parts are most important parts for the bridge saw machine. Under the bridge parts,we can also find a rotation table,this table can rotation 90-360 degree automatic,it can also turn over 85 degree for slab loading and unloading. We use a hydraulic part to work with rotation table, under the table you could find there are some pieces of hydraulic pumps. On the hydraulic part,there are a special motor for this part.

Precision and Accuracy:

Bridge saw machines are designed for precise and accurate cutting. The computerized control system enables operators to input specific measurements, ensuring the machine cuts the stone slabs with high precision. The cutting head’s movements are guided by precision linear rails or ball screws, minimizing errors and delivering consistent results.

Precision and accuracy are vital aspects of bridge saw machines. Here’s a more detailed explanation of how these machines achieve precise and accurate cuts:

Robust Structure:

Bridge saw machines are constructed with a sturdy and rigid structure to minimize vibrations and ensure stability during cutting. The bridge, cutting head, and worktable are engineered to withstand the cutting forces and maintain consistent positioning. This structural integrity contributes to the overall precision of the machine.

Cutting Head Control:

The cutting head of a bridge saw machine is equipped with motors and control systems that enable precise movements. The horizontal and vertical movements of the cutting head are typically controlled by computerized systems. These systems allow for accurate positioning of the cutting head to achieve precise cuts and maintain consistent dimensions.

Computerized Control System:

Modern bridge saw machines often feature advanced computerized control systems. Operators can input specific cutting parameters, such as dimensions and angles, into the control system. The system then coordinates the movements of the cutting head, the speed of the blade, and other variables to execute precise cuts according to the programmed instructions.

Measurement Tools and Sensors:

Bridge saw machines may incorporate measurement tools and sensors to enhance precision and accuracy. Laser guides, digital measuring systems, or cameras can be used to provide real-time measurements and assist in aligning the stone slabs for precise cuts. These measurement tools help operators achieve consistent results and minimize errors.

Repeatable Cutting Programs:

Bridge saw machines often allow operators to save cutting programs for specific shapes or dimensions. Once a cutting program is created, it can be easily recalled and executed for future cuts. This feature ensures consistency and accuracy, as the machine can replicate the same cuts repeatedly without relying solely on operator skill.

Waterjet System:

The waterjet system, which sprays water onto the cutting area during operation, also contributes to precision and accuracy. By cooling the blade and reducing friction, the waterjet system helps maintain the optimal cutting conditions. It prevents heat-related distortions and reduces the risk of material damage, resulting in cleaner and more accurate cuts.

Calibration and Maintenance:

Regular calibration and maintenance of bridge saw machines are crucial for sustaining precision and accuracy. The machine’s components, such as the cutting head, motors, and measuring systems, should be periodically checked and adjusted as needed. Proper maintenance ensures that the machine operates optimally, minimizing any deviations that could affect cutting precision.

Operator Skill and Training:

While bridge saw machines offer advanced automation and precision, operator skill and training remain important factors in achieving accurate cuts. Operators must be knowledgeable about the machine’s capabilities, understand the cutting parameters, and follow best practices for setup and operation. Proper training ensures that operators can optimize the machine’s performance and make necessary adjustments for specific cutting requirements.

Precision and accuracy are fundamental in the stone fabrication industry, where even small deviations can significantly impact the quality of the final product. Bridge saw machines combine robust construction, advanced control systems, measurement tools, and proper maintenance to achieve precise and accurate cuts consistently.

Automation and Technology:

Advanced bridge saw machines incorporate automation and technological features to enhance efficiency and ease of use. Some machines include laser or digital templating systems to precisely measure and replicate complex shapes. Additionally, computer numerical control (CNC) systems can automate the cutting process, reducing human error and improving productivity.

Certainly! Automation and technology play significant roles in the operation of bridge saw machines. Here’s a more detailed explanation of how automation and technology are integrated into these machines:

Computerized Control System:

Bridge saw machines feature computerized control systems that automate various aspects of the cutting process. These systems allow operators to input specific cutting parameters, such as dimensions and angles, into the machine. The control system then coordinates the movements of the cutting head, blade speed, water cooling, and other variables to execute precise cuts according to the programmed instructions.

Programmable Cutting Parameters:

The computerized control system enables the programming of cutting parameters for different stone materials and cutting requirements. Operators can save and recall cutting programs for specific shapes, dimensions, or cutting sequences. This automation ensures consistency and eliminates the need for manual adjustments for repeated cuts.

Touchscreen Interfaces:

Modern bridge saw machines often incorporate user-friendly touchscreen interfaces as part of their control systems. These interfaces provide intuitive controls for operators to input cutting parameters, monitor cutting progress, and adjust settings. Touchscreen interfaces simplify the operation of the machine and improve efficiency.

Digital Measurement Systems:

Bridge saw machines can incorporate digital measurement systems to assist in the precise positioning and alignment of stone slabs. Laser guides, digital scales, or cameras can be used to provide real-time measurements and aid in aligning the stone slabs accurately. These measurement systems enhance precision and reduce the reliance on manual measurement tools.

Remote Monitoring and Control:

Advanced bridge saw machines may offer remote monitoring and control capabilities. This allows operators or supervisors to monitor the machine’s performance, view cutting progress, and make adjustments remotely. Remote access enables efficient troubleshooting, optimization of cutting parameters, and overall machine management.

Safety and Sensor Technology:

Automation and technology in bridge saw machines include safety features and sensor technology. Safety interlocks, emergency stop buttons, and blade guards are incorporated to protect operators and prevent accidents. Sensors may be used to detect material thickness, blade wear, or anomalies in the cutting process. These features enhance operator safety and contribute to the overall efficiency of the machine.

Integration with CAD/CAM Software:

Bridge saw machines can be integrated with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software systems. CAD/CAM software allows operators to create and modify cutting designs digitally, which can then be transferred to the bridge saw machine for execution. This integration streamlines the workflow, enhances precision, and facilitates complex cutting operations.

Data Logging and Analysis:

Automation and technology in bridge saw machines often include data logging and analysis capabilities. The machine can collect and store data related to cutting parameters, machine performance, and production statistics. This data can be analyzed to optimize cutting processes, track productivity, and identify areas for improvement.

By incorporating automation and advanced technology, bridge saw machines streamline the cutting process, improve precision and accuracy, and enhance overall productivity. These features enable efficient operation, reduce manual labor, and provide the capability to handle complex cutting tasks.

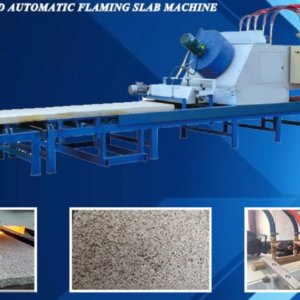

Bridge Saw Machine Details

Machine Loading And Packing

Bridge Saw Machine For Sale Specifications

| Item | Unit | Value |

|---|---|---|

| Blade Diameter | mm | ¢350-¢500 |

| Max.Cutting Size(LxWxH) | mm | 3200x3200x100 |

| Table Size(LxW) | mm | 3200x2000 |

| Table Turnover | n° | 0°-85° |

| Table Rotation | n° | 0-360 |

| Main Motor | kw | 15 |

| Total Power | kw | 20.2 |

| Water Consumption | m3/h | 3.5 |

| Machine Dimension(LxWxH) | mm | 6000x5000x2600 |

| Weight | kg | 6500 |

<