1. Description of stone flaming machine

2. Features of stone granite flaming machine

3. Key Benefits of Stone Flaming Machines

4. Applications of Stone Flaming Machines

5. Why buying a stone flaming machine from us

6. Details of Stone Flaming Machine

7. Specifications of Stone Flaming Machine

8. Stone Flaming Machine Vide

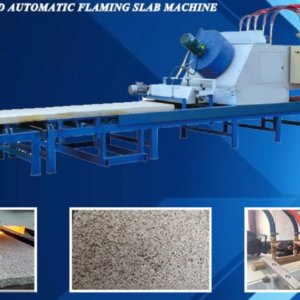

Description of stone flaming machine

Stone Flaming Machine is also named as stone burning machine. It’s a kind of special equipment for flaming treatment on marble granite and other stone material. Moved by chain and moving wheel, the stone is conveyed to the flaming area of the high-speed automatic stone flaming machine automatically. With characteristic of high automation, easy operation, even flaming surface, low energy cost, and high efficiency, the machine can be used to process 350 sqm/hour, which can save the labor intensity dramatically. Customers can choose different size of machine for flaming different width of stone materials such as 600mm, 800mm, 1000mm, 1200mm or other width. Stone Flaming Machine is composed of machine frame, stone conveying line, driving chain, span beam, walking frame, liquefied gas nozzle and variable frequency motor. We can also add a stone jib crane machine to do the slab loading and unloading, which would make greatly imporve the working efficiency. Many stone factories who buy this stone flaming machine also need granite bush hammer machine. In the realm of stone processing and finishing, few technologies have revolutionized the industry as profoundly as stone flaming machines. These powerful tools have become the go-to solution for achieving strikingly beautiful and durable stone surfaces. From enhancing the aesthetic appeal of natural stone to increasing its resistance against harsh weather conditions, stone flaming machines have become an indispensable asset in the stone industry. This article delves into the workings, benefits, and applications of stone flaming machines, shedding light on their transformative capabilities.

Stone flaming machines utilize a combination of heat and water to transform the surface of natural stones, such as granite, into a textured masterpiece. The process involves directing a controlled flame over the stone surface, causing the minerals within to expand and burst. Simultaneously, water is sprayed onto the heated surface, which cools and fractures the stone, creating a unique rough texture. The result is an aesthetically appealing surface that not only showcases the natural beauty of the stone but also enhances its durability.

Features of stone granite flaming machine

MosCut Stone Machine spent a huge number of time and money to do research and testing on this granite flaming machine. In the past 5 years, our engineer are continue testing this flaming machine with different spare parts and system. It can not only reduce labor intensity, improve product quality and production efficiency, but also save energy and reduce pollution. This stone granite flaming machine is characterized by reasonable design, advanced technology, delicate structure, fashionable appearance, convenient operation, energy saving, green environmental protection, good product quality and high production efficiency. Compared with traditional manual operation, automatic stone flaming machine has greatly reduced labor intensity of workers, reduced environmental pollution, increased production efficiency by more than times, reduced product breakage rate, and completely changed the phenomenon of quality instability caused by the uneven heating of the board surface by manual operation.

Key Benefits of Stone Flaming Machines:

Aesthetics:

Stone flaming machines impart an exquisite texture to the surface of natural stones, enhancing their visual appeal. The roughened texture creates captivating patterns and contrasts, adding depth and character to the stone. This unique finish can transform an ordinary stone into a centerpiece of elegance, making it a popular choice for interior and exterior applications.

Slip Resistance:

The textured surface created by stone flaming significantly improves slip resistance, making it an ideal choice for outdoor applications such as driveways, walkways, and pool decks. The enhanced grip ensures better traction, reducing the risk of accidents, especially in areas prone to moisture and wet conditions.

Durability:

Stone flaming enhances the structural integrity of natural stones. The process of heating and cooling creates microfractures on the surface, making it more resistant to freeze-thaw cycles, temperature variations, and heavy foot traffic. Flamed stones exhibit exceptional resilience and longevity, making them suitable for high-traffic areas that demand superior strength and endurance.

Weather Resistance:

The roughened texture and increased porosity resulting from stone flaming improve the stone’s ability to withstand weathering and natural elements. Flamed stones are less susceptible to cracking, chipping, and erosion caused by wind, rain, and UV radiation. This makes them an excellent choice for exterior cladding, paving, and landscaping applications.

Applications of Stone Flaming Machines:

Architecture and Construction:

Stone flaming machines find extensive use in architectural projects where aesthetics, durability, and safety are of paramount importance. Flamed stones are commonly used for exterior facades, wall claddings, flooring, and stairs in commercial and residential buildings.

Landscaping:

Stone flaming machines offer endless possibilities in landscape design. Flamed stones can be employed to create captivating pathways, patios, garden walls, and water features, adding a touch of natural beauty to outdoor spaces.

Monuments and Memorials:

The textured finish achieved by stone flaming machines is highly sought after in the creation of monuments and memorials. The rugged appearance conveys strength and timelessness, making it an appropriate choice for commemorative structures.

Why buying a stone flaming machine from us

1. Process and Control:

Stone flaming machines are equipped with advanced control systems that allow operators to precisely regulate the temperature and duration of the flame, as well as the water pressure and distribution. This level of control ensures consistent and uniform results across the entire stone surface.

2. Stone Selection:

While stone flaming is most commonly performed on granite due to its durability and natural beauty, the technique can also be applied to other types of stones such as limestone and slate. The suitability of a stone for flaming depends on its mineral composition and structural integrity.

3. Customization Options:

Stone flaming machines offer customization options to cater to diverse design preferences. The intensity of the flame can be adjusted to create different levels of texture, ranging from a light, subtle effect to a more pronounced and rugged surface. This versatility allows designers and architects to achieve the desired aesthetic outcome for their projects.

4. Maintenance:

Flamed stone surfaces require minimal maintenance. The rough texture makes them less susceptible to visible wear and tear, and their slip-resistant properties reduce the need for frequent cleaning. Regular sweeping and occasional pressure washing are usually sufficient to maintain the stone’s appearance and functionality.

5. Environmental Considerations:

Stone flaming is an environmentally friendly process. It does not involve the use of any harmful chemicals or produce significant waste. The heat used in the flaming process is generated using clean-burning fuels, such as propane or natural gas, which minimizes the environmental impact.

6. Integration with Other Stone Finishing Techniques:

Stone flaming can be combined with other stone finishing techniques, such as brushing, honing, or polishing, to achieve unique and striking results. This allows for even greater versatility and creativity in stone surface design.

7. Cost Considerations:

The cost of stone flaming depends on various factors, including the size of the stone, the complexity of the design, and the specific requirements of the project. While stone flaming may add some expense to the overall stone processing budget, the benefits it brings in terms of aesthetics, durability, and safety often justify the investment.

Stone flaming machines have revolutionized the stone industry, offering an innovative way to enhance the beauty and durability of natural stones. With their ability to transform ordinary stones into captivating works of art, these machines have found applications in a wide range of architectural, landscaping, and commemorative projects. By combining aesthetic appeal with slip resistance, weather resistance, and longevity, stone flaming machines have become an invaluable asset in the pursuit of exquisite stone surfaces that stand the test of time. As technology continues to advance, stone flaming machines are likely to evolve further, offering even more precise control, automation, and efficiency. With their ability to transform raw stone into captivating works of art, these machines will continue to play a crucial role in the stone industry, enabling architects, designers, and builders to create stunning and enduring stone surfaces.

Details of Stone Flaming Machine

Specifications of Stone Flaming Machine

| Item | Value | Value | Value | Value |

|---|---|---|---|---|

| Number of Nozzles | 10 | 14 | 18 | 24 |

| Process width | 600mm | 800mm | 1000mm | 1300mm |

| Output/hour | 100-160m² | 120-180m² | 160-220m² | 200-280m² |

| Power | 4KW | 4KW | 4KW | 4KW |

| Voltage | 380V | 380V | 380V | 380V |