1. GRP Pipe Cutting Made Easy with CNC Wire Saw Machines

2. What is a CNC Wire Saw Machine?

3. Specifications of CNC Wire Saw Machine

4. Features of Wire Saw Machine for GRP Pipe Cutting

5. Applications of GRP Pipe Wire Saw Machine

6. Maintenance and Operation Costs

7. How does the cost of a wire saw machine compare to other cutting machines?

8. Cutting speed and efficiency of GRP Pipe wire saw machine

9. How long should i replace a new diamond rope saw and what is the cost

GRP Pipe Cutting Made Easy with CNC Wire Saw Machines

GRP pipes, or glass-reinforced plastic pipes, they are commonly used in industries such as oil and gas, water treatment, and chemical processing due to their excellent corrosion resistance, high strength, and durability. GRP pipes are also lightweight and easy to install, making them a popular choice for a wide range of applications. However, cutting GRP pipes can be challenging due to their tough and abrasive nature. That’s where CNC wire saw machines come in.

What is a CNC Wire Saw Machine?

A CNC wire saw machine is a type of cutting machine that uses a wire with diamond beads to cut through materials such as metal, stone, and GRP pipes. The wire is guided by a computer-controlled system to ensure precision and accuracy in the cutting process. A CNC wire saw machine is a type of cutting machine that uses a thin, flexible wire with diamond beads to cut through materials. The wire is guided by a computer-controlled system, which ensures precision and accuracy in the cutting process. CNC wire saw machines are commonly used in industries such as metalworking, stone cutting, and GRP pipe cutting, where precision and accuracy are essential.

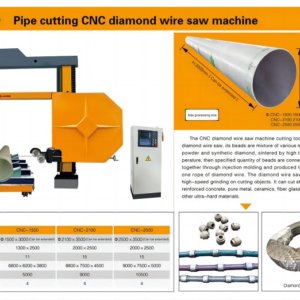

Specifications of CNC Wire Saw Machine

| Item Name | CNC diamond wire saw machine | ||

|---|---|---|---|

| Model Number | CNC-2000 | CNC-2500 | CNC-3000 |

| Max processing size | 3000x2000x1500mm | 3000x2500x1500mm | 3000x3000x1500mm |

| Dimension of Worktable | 2500x1300mm | 2500x1300mm | 2500x1300mm |

| Main Motor | 7.5kw | 7.5kw | 7.5kw |

| Water consuption | 4m³/h | 4m³/h | 4m³/h |

| Outline dimension | 6500X6300X3800mm | 7000X6300X3800mm | 7500X6300X3800mm |

| Gross weight | 5000kgs | 5500kgs | 6000kgs |

Features of Wire Saw Machine for GRP Pipe Cutting

Wire saw machines designed for cutting GRP pipe are typically equipped with specific features that make the process efficient and effective. For example, they may have a high cutting speed, which reduces the processing time and increases productivity. They may also have a computer-controlled system that ensures accurate and precise cutting, resulting in clean and smooth edges. Additionally, wire saw machines may produce minimal material waste, which is beneficial for reducing costs and environmental impact. Finally, they may be designed for durability and require minimal maintenance, which reduces downtime and increases efficiency. Wire saw machines designed for cutting GRP pipes have specific features that make the process efficient and effective. These features include:

1. High Cutting Speed:

Wire saw machines can cut through GRP pipes quickly, which reduces the processing time and increases productivity.

2. Precision Cutting:

The computer-controlled system ensures accurate and precise cutting, resulting in clean and smooth edges.

3. Minimal Material Waste:

Wire saw machines produce minimal material waste, which is beneficial for reducing costs and environmental impact.

4. Low Maintenance:

Wire saw machines are designed to be durable and require minimal maintenance, which reduces downtime and increases efficiency.

Applications of GRP Pipe Wire Saw Machine

Wire saw machines are commonly used in the GRP pipe industry for various applications. For example, they can be used to cut GRP pipes into custom lengths and shapes to meet specific project requirements. They can also be used to cut damaged sections of GRP pipes during repair and maintenance work. Additionally, wire saw machines can be used in the production of GRP pipes, cutting them to the required lengths during the manufacturing process. Wire saw machines are commonly used in the following applications in the GRP pipe industry:

1. Custom Pipe Cutting:

Wire saw machines can cut GRP pipes into custom lengths and shapes to meet specific project requirements.

2. Repair and Maintenance:

Wire saw machines can be used to cut damaged sections of GRP pipes to repair and restore them to their original condition.

3. Production:

Wire saw machines can be used in the production of GRP pipes, cutting them to the required lengths during the manufacturing process.

Maintenance and Operation Costs

Maintaining and operating a wire saw machine for GRP pipe cutting requires minimal costs. While the diamond beads on the wire will need to be replaced periodically, depending on usage, this is a relatively low-cost maintenance requirement. Additionally, wire saw machines are designed for ease of use, with minimal training required to operate them. This makes them a cost-effective solution for companies in the GRP pipe industry, as they can increase productivity and reduce costs in the long run.

In conclusion, wire saw machines are a valuable tool for cutting GRP pipes efficiently and accurately. Their high cutting speed, precision cutting, minimal material waste, and low maintenance make them a cost-effective solution for companies in the GRP pipe industry. By investing in a wire saw machine, companies can increase their productivity and reduce their costs in the long run.

How does the cost of a wire saw machine compare to other cutting machines?

The cost of a wire saw machine for GRP pipe cutting can vary depending on the size, capacity, and features of the machine. However, in general, wire saw machines tend to be more expensive than other cutting machines such as a bandsaw or a hacksaw. This is because wire saw machines use diamond beads on a thin, flexible wire to cut through hard materials like GRP pipes, which requires specialized technology and materials.

Despite the higher initial cost, wire saw machines can be a cost-effective solution in the long run due to their high cutting speed, precision cutting, minimal material waste, and low maintenance requirements. By increasing productivity and reducing material waste, wire saw machines can help companies save money on labor and material costs over time. Additionally, their durability and low maintenance requirements can reduce downtime and increase overall efficiency.

Cutting speed and efficiency of GRP Pipe wire saw machine

The cutting speed and efficiency of a wire saw machine for GRP pipe cutting can vary depending on the machine’s specifications and the size and thickness of the pipes being cut.

In general, wire saw machines can cut through GRP pipes quickly and efficiently compared to other cutting methods. This is because the diamond beads on the wire are highly abrasive and can cut through hard materials like GRP with ease. Additionally, the computer-controlled system ensures accurate and precise cutting, resulting in clean and smooth edges.

The cutting speed of a wire saw machine for GRP pipe cutting can range from several centimeters per minute to several meters per minute, depending on the machine’s capacity and the material being cut. This high cutting speed can help increase productivity and reduce processing time, making wire saw machines an efficient solution for cutting GRP pipes.

Furthermore, wire saw machines produce minimal material waste, which is beneficial for reducing costs and environmental impact. This is because the wire is very thin, so the kerf, or the width of the cut, is minimal. This means that more of the material is preserved, reducing the amount of waste that needs to be disposed of.

Wire saw machines for GRP pipe cutting are a highly efficient and effective solution for cutting GRP pipes quickly and accurately while minimizing material waste.

how long should i replace a new diamond rope saw and what is the cost

The frequency of replacing the diamond rope saw on a wire saw machine for GRP pipe cutting can vary depending on several factors, such as the machine’s usage, the cutting conditions, and the quality of the diamond rope saw. Typically, the diamond rope saw needs to be replaced when it becomes worn or damaged, which can result in a decrease in cutting performance and accuracy.

As a general guideline, the diamond rope saw on a wire saw machine may need to be replaced after about 50 to 100 hours of cutting, depending on the factors mentioned above. However, some diamond rope saws may last longer or shorter than this, depending on their quality and the conditions they are used in.

The cost of a new diamond rope saw for a wire saw machine can also vary depending on the quality, size, and type of diamond beads used. Diamond rope saws with high-quality diamond beads tend to be more expensive, but they also offer longer service life and better cutting performance. On average, the cost of a new diamond rope saw for a wire saw machine can range from a few hundred dollars to several thousand dollars.

It’s important to note that the cost of replacing the diamond rope saw should be factored into the overall operating cost of the wire saw machine. However, the minimal material waste and high cutting efficiency of wire saw machines can help offset the cost of replacing the diamond rope saw over time.