1. Description of 5 Axis CNC Bridge Saw Machine

2. Feature of 5 axis CNC bridge saw machine

3. Differences between regular bridge saw and 5 axis cnc bridge saw

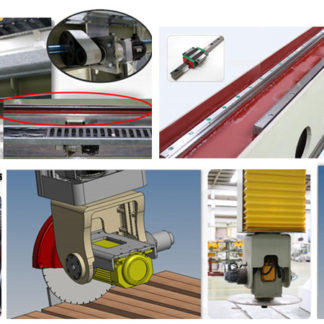

4. Details of 5 Axis CNC Bridge Saw Machine

5. Specifications of 5 Axis CNC Bridge Saw Machine

Description of 5 Axis CNC Bridge Saw Machine

CNC Bridge saw machines are powerful and highly accurate machines that are used in the stone cutting industry for cutting and shaping large slabs of natural or engineered stone. They are essential for any stone fabrication shop as they can quickly process large volumes of stone and cut it into precise sizes and shapes. 5 axis cnc bridge saw machine is a high tech machine with five-axis linkage system,this system is developed base on a kind of PC stone processing system. The blade is control by three straight axis and two rotation axis,the two rotation axis are rotating with X axis and Z axis. This 5 axis cnc bridge saw machine is mainly used for processing high valued stone products with hyperspace complex surface. It can do both cutting,engraving and mining full automatically. Technology innovation is happening on stone industry,and our cnc bridge saw machine is designed out base on this new background.

Feature of 5 axis CNC bridge saw machine

The numerical control system of cnc bridge saw machine is working under PC system, this PC system is a special system for five-axis linkage stone sawing, it can finish 5 abnormity bent surfaces in one time. This machine and stone polishing machine are the basic machines for most of stone factories.

With cnc bridge saw machine,customers can make the stone drawings on machine computer or upload CAD drawings through USB. The system would show you simulation demo after read the drawings.

You can stop the machine and reset parameters during cnc bridge saw machine running and then reprocessing from the beginning or go ahead to processing.

The data of cnc bridge saw machine is storage as modules and could be called manually.

The processing parameters can be adjusted manually without stop the machine, the codes inside cnc bridge saw machine will renew automatically according to the adjustment.

This CNC bridge saw machine has a very high precision processing and suitable for mosaic works.

CNC Bridge Saw Machine contains a infrared light device. With this device,work pieces can be put on table quickly.

Machine can be connected to the internet, operators could control machine running remotely through internet and technical could checking problems easily online. CNC Bridge Saw Machine Max processing size is 3200*2000*200mm, Blade diameter is 600mm

1. Size and Capacity:

CNC Bridge saw machines come in different sizes and capacities, depending on the size of the slabs being cut. Smaller machines are typically used for residential and commercial projects, while larger machines are used for industrial projects. The size of the saw blade also varies, with larger blades being used for thicker materials.

2. Cutting Precision:

CNC Bridge saw machines are designed to cut stone with high precision, ensuring that each cut is exactly as per design specifications. The saw blades are typically made of high-quality diamond and are capable of cutting through even the hardest materials. The machines are equipped with advanced computer software that allows for accurate cutting and shaping of stone pieces.

3. Automation:

Many CNC bridge saw machines are automated, meaning that they can be programmed to cut and shape stone pieces without requiring manual intervention. This feature can significantly reduce production time and improve cutting accuracy, making it an excellent investment for stone cutting businesses.

4. Safety Features:

CNC Bridge saw machines are equipped with various safety features to protect operators and prevent accidents. These features include safety guards, emergency stop buttons, and automatic shut-off systems that activate when the machine encounters an obstacle.

5. Maintenance and Upkeep:

CNC Bridge saw machines require regular maintenance to ensure that they continue to operate smoothly and efficiently. This includes regular cleaning, lubrication, and blade sharpening. Regular upkeep can extend the life of the machine and prevent costly breakdowns.

6. Cost:

The cost of a 5 Axis CNC bridge saw machine can vary greatly, depending on the size, capacity, and features of the machine. Smaller machines can cost a few thousand dollars, while larger, more advanced machines can cost several hundred thousand dollars.

Differences between regular bridge saw and 5 axis cnc bridge saw

1. Cutting Capability:

– Regular Bridge Saw Machine: A regular bridge saw typically operates in three axes (X, Y, and Z), allowing straight cuts and basic profiling.

– 5-Axis CNC Bridge Saw Machine: A 5-axis CNC bridge saw has the capability to move the cutting blade in five axes (X, Y, Z, and two additional rotational axes). This enables the machine to perform complex cuts, intricate profiling, beveling, and sculpting.

2. Flexibility and Versatility:

– Regular Bridge Saw Machine: A regular bridge saw is suitable for basic cutting tasks and may have limitations when it comes to complex and artistic cuts.

– 5-Axis CNC Bridge Saw Machine: The 5-axis CNC bridge saw offers enhanced versatility, allowing operators to execute intricate designs and complex shapes. It provides more freedom and flexibility in creating custom cuts and designs.

3. Automation and Precision:

– Regular Bridge Saw Machine: Regular bridge saw machines typically require manual adjustments for each cut, which can be time-consuming and may have limitations in achieving precise cuts.

– 5-Axis CNC Bridge Saw Machine: 5-axis CNC bridge saw machines feature advanced computer control and automation. They offer precise and accurate cutting through automated adjustments, ensuring consistent results for each cut.

4. Programming and Software:

– Regular Bridge Saw Machine: Regular bridge saw machines usually have simpler control systems with basic programming options, making them easier to operate.

– 5-Axis CNC Bridge Saw Machine: 5-axis CNC bridge saw machines require more advanced programming. They use specialized software that allows operators to create and import complex designs, control cutting paths, and execute intricate cuts with precision.

5. Time Efficiency:

– Regular Bridge Saw Machine: Regular bridge saw machines may require more time for complex cuts or profiling due to manual adjustments and limitations in movement.

– 5-Axis CNC Bridge Saw Machine: 5-axis CNC bridge saw machines can significantly reduce the time required for complex cuts. Their advanced automation and precision allow for faster production of intricate designs.

6. Cost:

– Regular Bridge Saw Machine: Regular bridge saw machines are generally more affordable compared to 5-axis CNC bridge saw machines.

– 5-Axis CNC Bridge Saw Machine: 5-axis CNC bridge saw machines are more sophisticated and technologically advanced, making them more expensive than regular bridge saw machines.

These are some of the key differences between regular bridge saw machines and 5-axis CNC bridge saw machines. The choice between the two depends on your specific requirements, budget, and the complexity of cuts or designs you need to produce.

Details of 5 Axis CNC Bridge Saw Machine

Specifications of 5 Axis CNC Bridge Saw Machine

| Item | Value | Unit |

|---|---|---|

| Diameter of saw blade | ø350-ø650 | mm |

| Dimension of working platform | 350x210 | cm |

| Max. cutting length | 350 | cm |

| Max. cutting thickness | 190 | mm |

| Max. lifting stroke | 500 | mm |

| Power of main motor | 15 | kw |

| Power of cutter frame reciproctating motor | 1.15 | kw |

| Power of crossbeam shifting motor | 1.15 | kw |

| Power of hydraulic station motor | 2.2 | kw |

| Power of lifting motor | 0.85 | kw |

| Gross power | 30.35 | kw |

| Water consumption | 2 | m3/h |

| Gross weight | 5800 | kg |

| Dimensions (L x W x H) | 630x360x310 | cm |