1. Introduce of baluster cutting machine

2. Why buying baluster cutting machine from us

3. How long does the machine take to cut one baluster?

4. Baluster cutting machine maximum cutting size

5. Factors that affect the speed of baluster cutting machine

6. Can the machine cut balusters with different shapes and sizes?

7. How does the machine ensure that the cuts are accurate?

8. Details of Baluster Cutting Machine

9. Stone Baluster Profiling Machine Specifications

10. Baluster Cutting Profiling Machine Video

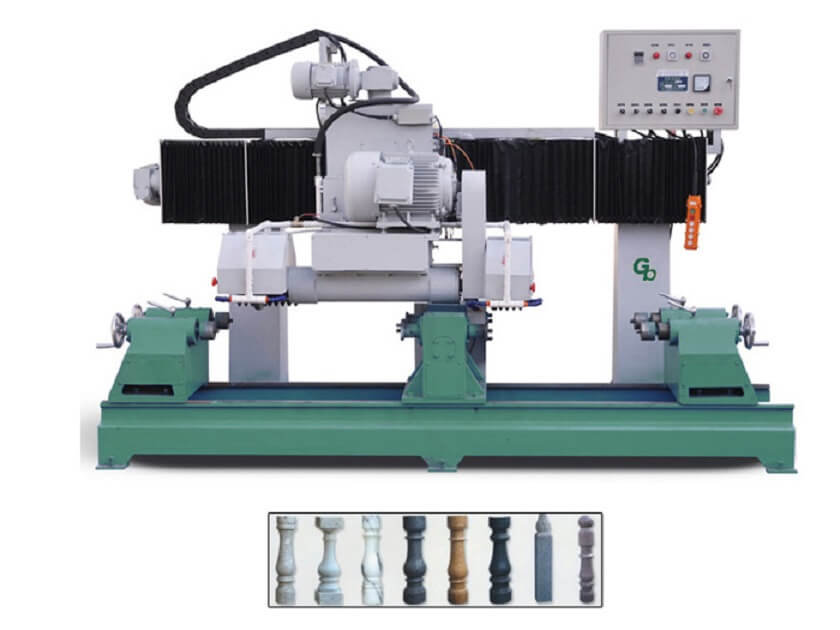

Introduce of baluster cutting machine

Baluster Cutting Profiling machine is a easy and powerful machine for cutting marble and granite.

Here we show only one of our models, we have other models which can cut two balusters,four balusters and even more balusters in one time.With this machine,you can easily make small columns and balusters products for home declaration and other stone applications.

As a professional manufacturer of stone cutting machines, we are proud to introduce our baluster cutting machine. This machine is designed to cut balusters with precision and efficiency, making it an essential tool for businesses in the stone cutting industry. The baluster cutting machine is a type of stone cutting machine that is used to cut balusters, which are decorative supports typically used in railings, staircases, and other architectural features. The machine consists of a cutting head, a blade, and a feeding system that moves the stone through the cutting process.

One of the main features of our baluster cutting machine is its high level of precision. The machine is equipped with advanced technology that ensures the blade moves in a straight line, resulting in clean and accurate cuts. This level of precision is essential for businesses that require high-quality cuts for their projects.

Another feature of our baluster cutting machine is its efficiency. The machine is designed to cut balusters at a much faster rate than traditional methods, which means that businesses can complete projects more quickly and efficiently. This increased productivity can lead to higher profits and greater customer satisfaction.

In addition to its precision and efficiency, our baluster cutting machine also offers a high level of safety. The machine is equipped with safety features that prevent accidents and injuries. For example, the machine is designed with sensors that detect when an object is too close to the blade, which causes the machine to stop automatically. This feature ensures that workers are safe from harm while operating the machine.

Our baluster cutting machine is also easy to use and maintain. The machine is designed with user-friendly controls and requires minimal maintenance, which means that businesses can focus on their projects instead of spending time and resources on upkeep.

Our baluster cutting machine is a valuable tool for businesses in the stone cutting industry. It offers a high level of precision, efficiency, and safety, which can help businesses increase profits and improve customer satisfaction. If you are looking for a reliable and efficient baluster cutting machine, look no further than our product. We are confident that it will exceed your expectations and help you take your business to the next level.

Why buying baluster cutting machine from us

Cut a variety shapes and sizes

The baluster cutting machine is a versatile machine that can cut a variety of shapes and sizes of balusters. It can cut both straight and curved balusters, making it ideal for a wide range of projects. Our baluster cutting machine is also customizable, which means that it can be tailored to meet the specific needs of our customers. We offer a range of blade sizes and types to ensure that the machine can cut through different types of stone with ease. We can also adjust the feeding system to accommodate different sizes and shapes of stone.

Energy-efficient designed

One of the advantages of our baluster cutting machine is that it is designed to be energy-efficient. The machine uses a minimal amount of energy to operate, which can help businesses save money on their energy bills. This feature also makes the machine more environmentally friendly, which is important in today’s world.

Durable and long-lasting

In addition to its efficiency and precision, our baluster cutting machine is also durable and long-lasting. The machine is made from high-quality materials and is designed to withstand the rigors of daily use. This means that businesses can rely on the machine to perform consistently and reliably for years to come.

customer service and support

We offer excellent customer service and support for our baluster cutting machine. We provide training and support to our customers to ensure that they are able to use the machine to its full potential. We also offer maintenance and repair services to keep the machine running smoothly and to address any issues that may arise.

Valuable Investment

Baluster cutting machine is a valuable investment for any business in the stone cutting industry. It offers a range of features and benefits that can help businesses increase productivity, improve efficiency, and enhance the quality of their work. If you are interested in learning more about our baluster cutting machine or any of our other stone cutting machines, please do not hesitate to contact us. We would be happy to answer any questions you may have and provide you with more information.

How long does the machine take to cut one baluster?

The time it takes for the baluster cutting machine to cut a baluster can vary depending on several factors, such as the size and shape of the baluster, the type of stone being cut, and the speed at which the machine is set to operate. However, in general, our baluster cutting machine is designed to cut balusters at a much faster rate than traditional methods.

For example, when cutting a 4-inch diameter baluster from granite, our baluster cutting machine can typically complete the job in just a few minutes. This is significantly faster than manual methods, which can take several hours to complete the same task.

It’s important to note that the speed at which the machine operates can be adjusted to suit the needs of the project. If precision is more important than speed, the machine can be set to operate at a slower speed to ensure that the cuts are as accurate as possible. Conversely, if speed is a priority, the machine can be set to operate at a faster speed to complete the job more quickly.

Ultimately, the time it takes for the baluster cutting machine to cut a baluster will depend on the specific requirements of the project. However, our machine is designed to operate efficiently and quickly, which can help businesses complete projects more quickly and efficiently.

Baluster cutting machine maximum cutting size

The maximum size of balusters that the machine can cut will depend on the specific model and specifications of the baluster cutting machine. However, our baluster cutting machine is designed to cut a wide range of sizes and shapes of balusters.

For example, our machine can typically cut balusters with a diameter of up to 12 inches and a height of up to 36 inches. This range covers a wide variety of baluster sizes commonly used in the stone cutting industry.

It’s important to note that the machine can be customized to meet the specific needs of our customers. For example, we can adjust the feeding system to accommodate larger or smaller stones, or we can provide a larger blade to cut thicker pieces of stone.

If you have specific requirements for the size of balusters you need to cut, we recommend speaking with our team to determine if our baluster cutting machine is the best fit for your needs. We can provide you with more information about the capabilities of our machine and help you select the best options for your specific project requirements.

Factors that affect the speed of baluster cutting machine

There are several factors that can affect the speed of a baluster cutting machine. These include:

1. Size and shape of the baluster:

The larger and more complex the baluster, the longer it will take to cut. Balusters with intricate designs or curves may require more time to cut than simpler, straight balusters.

2. Type of stone:

Different types of stone have different densities and hardness, which can affect the speed at which they can be cut. Harder stones, such as granite, may take longer to cut than softer stones, such as marble.

3. Blade size and type:

The size and type of the blade used in the machine can also affect the cutting speed. Larger blades can cut through thicker pieces of stone more quickly than smaller blades, while diamond blades are specifically designed for cutting harder stones and can cut more quickly than other types of blades.

4. Cutting speed:

The speed at which the machine is set to operate can also affect the cutting speed. Higher speeds can cut through stone more quickly, but may sacrifice precision, while slower speeds may produce more precise cuts but take longer to complete.

5. Machine maintenance:

Regular maintenance of the machine, such as cleaning and blade sharpening, can help ensure that it is operating at peak efficiency. Neglecting maintenance can lead to slower cutting times and reduced performance.

By taking these factors into account, businesses can optimize the cutting speed of their baluster cutting machine and ensure that they are getting the most out of their investment.

Can the machine cut balusters with different shapes and sizes?

Yes, our baluster cutting machine is capable of cutting balusters of different shapes and sizes. The machine is designed to be versatile and flexible, which means that it can be adjusted to cut a wide range of baluster shapes and sizes.

The machine is equipped with a feeding system that can be adjusted to accommodate different sizes and shapes of stone. This means that the machine can cut both straight and curved balusters, as well as balusters with intricate designs and shapes.

In addition, we offer a range of blade sizes and types to ensure that the machine can cut through different types of stone with ease. This means that the machine can be customized to meet the specific needs of our customers.

Whether you need to cut simple, straight balusters or more complex and intricate designs, our baluster cutting machine is up to the task. Our team of experts can work with you to determine the best options for your specific project requirements and ensure that the machine is optimized for your needs.

How does the machine ensure that the cuts are accurate?

Our baluster cutting machine is designed to ensure that the cuts are accurate and precise. The machine is equipped with advanced technology and features that help to maintain a high level of cutting accuracy.

Cutting Heads

One of the main features that helps to ensure accuracy is the cutting head itself. The cutting head is designed to move in a straight line, which helps to maintain a consistent cutting depth and angle. This ensures that the finished balusters are straight, even, and consistent in size and shape.

Sensors and Controls on the machine

In addition, the machine is equipped with a range of sensors and controls that help to ensure accuracy. For example, the machine may include a laser sensor that detects the position of the stone and adjusts the cutting head to ensure that the cuts are made in the correct location. The machine may also include a digital readout that displays the position of the blade, allowing the operator to make precise adjustments as needed.

User-friendly and easy to operate

To further ensure accuracy, our baluster cutting machine is designed to be user-friendly and easy to operate. The controls are intuitive and easy to understand, which helps to minimize the risk of operator error and ensure that the cuts are made correctly.

Regular maintenance and calibration

Regular maintenance and calibration of the machine can also help to ensure accuracy. Our team of experts can provide training and support to help our customers maintain their machine and ensure that it is operating at peak efficiency.

Our baluster cutting machine is designed to ensure that the cuts are accurate and precise. The machine is equipped with a range of advanced features and technology that help to maintain a high level of cutting accuracy, and our team is committed to providing the support and training necessary to ensure that our customers get the most out of their investment.

Details of Baluster Cutting Machine

Stone Baluster Profiling Machine Specifications

| Power of motor | 11kw |

|---|---|

| Max.Cutting Length | 1000mm |

| Dimension | 3500x1500x 2000mm |

| Max. Diameter of the pillar | Φ340mm |

| Diameter of the blade | 300mm, 350mm, 600mm |

| Weight | 2800kgs |

| Water consumption | 3m3/h |

| Style | Stepless speed adjusting |