Stone Veneer Saw Machine for Wall Cladding

In the world of construction and interior design, stone veneer has become a popular choice for wall cladding due to its natural beauty, durability, and versatility. To achieve precise and efficient stone veneer cutting, specialized equipment like the stone veneer saw machine is essential. This article delves into the features, benefits, applications, and selection tips for these machines, providing a comprehensive guide for professionals and enthusiasts alike.

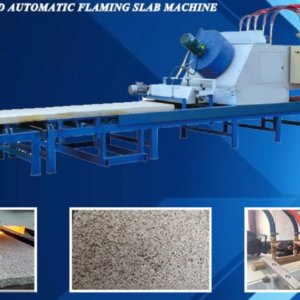

What is a Stone Veneer Saw Machine?

A stone veneer saw machine is a specialized cutting tool designed to process thin slices of natural or engineered stone into veneers. These veneers are then used for wall cladding, giving surfaces the appearance of solid stone without the weight or cost. The machine ensures clean, precise cuts, making it a must-have for contractors, stonemasons, and designers.

With the increasing demand for stone cutting in both residential and commercial projects, the stone veneer saw machine has become a critical piece of equipment in the construction industry.

Applications of Stone Veneer Saw Machines

Stone veneer saw machines are widely used in various applications, including:

1. Wall Cladding Projects: These machines are essential for cutting stone veneers to fit specific wall dimensions, ensuring a seamless and professional finish.

2. Interior Design: Stone veneers are used to create accent walls, fireplaces, and other decorative elements.

3. Exterior Facades: Stone veneer cladding enhances the aesthetic appeal and durability of building exteriors.

4. Landscaping: Veneers are also used for outdoor features like garden walls and pathways.

These machines can process a variety of stone types, including granite, marble, limestone, and slate, making them versatile tools for different projects.

Key Features of Stone Veneer Saw Machines

Modern stone veneer saw machines come equipped with advanced features to ensure efficiency and precision. Some of the key features include:

1. Precision Cutting: Laser-guided systems and adjustable blades ensure accurate cuts, reducing material waste.

2. Durability: Built with high-quality materials, these machines are designed to withstand heavy use in demanding environments.

3. Ease of Use: User-friendly controls and ergonomic designs make these machines accessible to both professionals and beginners.

4. Automation: Some models feature automated cutting systems, which increase productivity and consistency.

5. Safety Features: Blade guards, emergency stop buttons, and dust extraction systems enhance operator safety.

Benefits of Using Stone Veneer Saw Machines

Investing in a stone veneer saw machine offers numerous advantages:

1. Time Efficiency: These machines significantly reduce cutting time compared to manual methods, speeding up project timelines.

2. Cost-Effectiveness: Precision cutting minimizes material waste, saving costs in the long run.

3. High-Quality Finishes: Clean, accurate cuts result in professional-looking veneers that enhance the overall appearance of the project.

4. Versatility: The ability to process different types of stone makes these machines suitable for a wide range of applications.

5. Durability: Stone veneer cladding created with these machines is long-lasting and resistant to wear and tear.

Types of Stone Veneer Saw Machines

There are several types of stone veneer saw machines available, each suited to specific needs:

1. Manual Machines: Ideal for small-scale projects, these machines require manual operation but are cost-effective.

2. Automated Machines: Perfect for large-scale projects, these machines feature advanced automation for increased productivity.

3. Portable Machines: Lightweight and easy to transport, these machines are great for on-site work.

4. Stationary Machines: Designed for workshop use, these machines offer stability and precision for detailed work.

How to Choose the Right Stone Veneer Saw Machine

Selecting the right machine depends on your project requirements. Consider the following factors:

1. Project Scale: Choose manual machines for small projects and automated models for larger ones.

2. Stone Type: Ensure the machine is compatible with the type of stone you’ll be working with.

3. Blade Quality: High-quality blades ensure clean cuts and reduce the need for frequent replacements.

4. Motor Power: A powerful motor is essential for cutting dense materials like granite.

5. Safety Features: Look for machines with robust safety mechanisms to protect operators.

Maintenance and Care for Stone Veneer Saw Machines

Proper maintenance is crucial to ensure the longevity and performance of your machine. Follow these tips:

1. Regular Cleaning: Remove dust and debris after each use to prevent buildup.

2. Blade Sharpening: Keep the blade sharp to maintain cutting precision.

3. Lubrication: Regularly lubricate moving parts to reduce friction and wear.

4. Inspection: Periodically inspect the machine for any signs of damage or wear.

Case Studies and Success Stories

Many professionals have successfully used stone veneer saw machines to complete stunning projects. For example, a contractor in California used an automated stone veneer saw machine to complete a large-scale wall cladding project for a luxury hotel, achieving a flawless finish and reducing project time by 30%.

Industry Trends and Future Outlook

The stone veneer industry is evolving, with trends like eco-friendly materials and advanced automation shaping the future. Stone veneer saw machines are also becoming more sophisticated, with features like AI-guided cutting systems and enhanced safety mechanisms.

Stone veneer saw machines are indispensable tools for achieving high-quality wall cladding. Their precision, efficiency, and versatility make them a valuable investment for professionals in the construction and design industries. Whether you’re working on a small residential project or a large commercial development, choosing the right stone veneer saw machine can make all the difference.

Explore our range of stone veneer saw machines today and take your wall cladding projects to the next level!

Specifications of Stone Veneer Saw Machine for Wall Cladding

| Technical Parameter | 60HP | 30HP |

|---|---|---|

| Dimensions (L×W×H) | 3700mm×1600mm×1730mm | 3100mm×1600mm×1730mm |

| Machine Weight | 2720kg | 2040kg |

| Main Motor Power | 45kw | 22kw |

| Electricity | 3 Phase, 240/460V | 3 Phase, 240/460V |

| Amperage | 172/86A | 86/43A |

| Water Consumption | 3.5m³/h | 3m³/h |

| Blade Size | 1000mm-1200mm | 750mm |

| Blade Speed Standard(Adjustable) | 780rpm | 900rpm |

| Max. Cutting Depth | 300mm | 250mm |

| Conveyor Belt Speed(Adjustable) | 600mm/min-2450mm/min | 600mm/min-2450mm/min |