Introduction to CNC Wire Saw Technology

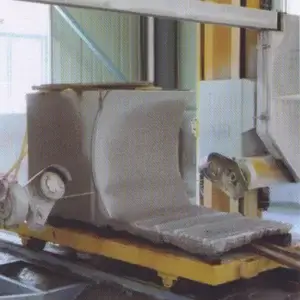

The CNC Wire Saw Machine, specifically designed for industrial stone cutting and profiling, has become a cornerstone in modern stone cutting facilities. Unlike mining-oriented wire saws, this variant focuses on precision cutting of stone blocks such as granite, marble, and engineered quartz. Equipped with advanced CNC systems like those developed by SINAD, these machines deliver unparalleled accuracy for architectural elements, countertops, and decorative stone products.

Technical Specifications of MCSJ-2000 Model

The MCSJ-2000 CNC Wire Saw Machine exemplifies cutting-edge engineering for stone processing. Below are its core technical parameters:

| Parameter | Value |

|---|---|

| Diameter of Wire | 8–10 mm |

| Length of Wire | 15,100 mm |

| Power of Main Motor | 11 kW |

| Max. Processing Size (L×W×H) | 2000 × 2000 × 1500 mm |

| Cutting Linear Speed | 25–45 m/s |

| Water Consumption | 2 m³/h |

| Gross Weight | 6800 kg |

| Dimensions (L×W×H) | 6000 × 7000 × 4000 mm |

Operational Advantages

1. Precision and Flexibility

Integrated with multi-axis CNC systems like the stone wire saw machine, the MCSJ-2000 achieves ±0.5 mm dimensional tolerance, ideal for intricate profiles and curved cuts. Its adaptive programming supports CAD/CAM file inputs (e.g., DXF formats), enabling rapid customization for bespoke designs.

2. High Efficiency and Automation

With a cutting speed of up to 45 m/s and 24/7 operational capability, this machine reduces production cycles by 60% compared to traditional methods. Automated wire tensioning and lubrication systems minimize manual intervention, aligning with Industry 4.0 standards observed.

3. Durability and Safety

The IP54-rated enclosure and diamond-embedded cutting wire ensure longevity in harsh environments. Safety features include emergency stop mechanisms and real-time vibration monitoring, compliant with CNAS-RL02 safety protocols (Webpage 7).

Industrial Applications

- Architectural Stonework: Producing curved staircases, columns, and façade elements.

- Countertop Manufacturing: Precision cutting for kitchen and vanity tops.

- Monument Crafting: Detailed engraving and shaping of memorial stones.

Why choose us

The MCSJ-2000 CNC Wire Saw Machine represents a paradigm shift in stone processing, combining precision, automation, and robustness. For manufacturers seeking to optimize their stone cutting workflows, this machine offers a future-proof solution backed by advanced CNC technology and ergonomic design.