Engraving Machine For Grave Headstones: Revolutionizing Memorialization

The finality of a loved one’s departure is marked not just by the memories we hold, but also by the tangible symbols we use to honor their lives. Grave Headstones, serving as a perennial testament to those who have passed, are a cornerstone of this memorial process. The art of crafting these monuments has evolved over centuries, and with the advent of modern technology, the Grave Headstone Engraver Machine has emerged as a pivotal tool in the field of memorialization. This article delves into the intricacies of these machines, their functionality, and their impact on the craft of creating lasting tributes.

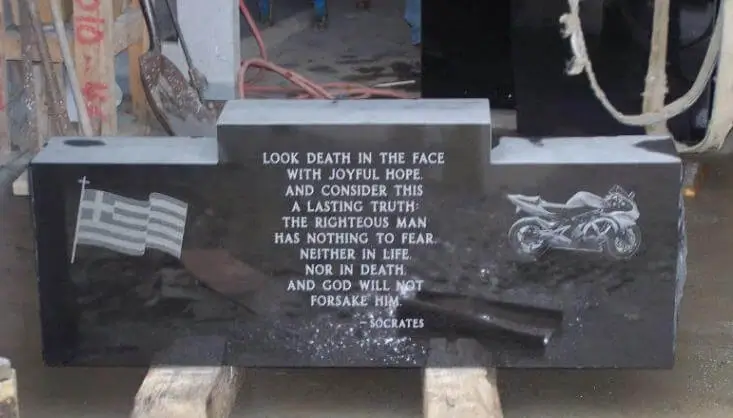

In the realm of memorialization, grave headstones play a crucial role in honoring the lives of those who have passed away. These enduring monuments serve as a lasting tribute, etching the names, dates, and often poignant epitaphs into stone. At the heart of this process lies a remarkable machine – the grave headstones engraver.

What is a Grave Headstone Engraver Machine?

A grave Headstone Engraver Machine is a sophisticated piece of equipment designed to inscribe epitaphs, dates, names, and decorative elements onto headstones. These machines range from manually operated devices to fully automated stone CNC machine (Computer Numerical Control) systems that can carve intricate designs with precision. They are capable of working with a variety of materials commonly used for headstones, such as granite, marble, slate, and other durable stones.

The grave headstones engraver is a specialized piece of equipment designed to carve intricate details onto the surfaces of various stone materials, including granite, marble, and sandstone. This machine combines precision engineering with advanced technology to create lasting inscriptions that withstand the test of time.

Types of Engraver Machines:

1. Manual Engravers: These are hand-operated tools requiring skilled craftsmen to guide the engraving process. While they offer a high degree of control and personal touch, they are labor-intensive and less consistent compared to their automated counterparts.

2. Semi-Automated Engravers: These machines combine manual oversight with some level of automation. They are typically guided by templates or stencils and can be more efficient than purely manual methods.

3. CNC Engravers: CNC engravers are at the forefront of grave engraving machine technology. They utilize digital designs and are controlled by computer software, allowing for precise and repeatable results. These machines can handle complex imagery and fonts with ease.

Key Components and How They Work:

The core components of a grave Headstone Engraver Machine include:

- Spindle: The primary cutting tool that rotates at high speeds to engrave the stone.

- Bed: A flat surface where the headstone is securely placed during the engraving process.

- Guides/Rails: These ensure smooth and precise movement of the spindle across the stone.

- Controller: In CNC machines, this is the brain that interprets the digital design and translates it into commands for the machine’s movements.

- Software: Design software is used to create detailed patterns and lettering that the machine will engrave into the stone.

The engraving process begins with the creation of a design using specialized software. Once the design is finalized, it is sent to the machine’s controller. The headstone material is then fixed onto the bed of the machine to ensure no shifting occurs during engraving. The spindle, equipped with a diamond-tipped bit or another appropriate cutter, moves over the surface of the stone following the design coordinates. As it moves, it carves out the design with precision and accuracy.

Advantages of Using Engraver Machines:

- Consistency: Automated machines produce uniform results, which is vital for maintaining quality in memorialization.

- Efficiency: CNC engravers significantly reduce the time needed to produce a headstone, enabling quicker turnarounds for clients.

- Versatility: With advanced software, a wide range of designs can be realized, from simple text to complex images.

- Safety: Reducing hands-on interaction with cutting tools lowers the risk of accidents for craftsmen.

The Grave Headstone Engraver Machine represents a significant leap forward in the field of memorialization. By marrying traditional craftsmanship with cutting-edge technology, these machines enhance our ability to commemorate loved ones with enduring elegance and respect. As technology continues to advance, we can expect these machines to become even more precise, efficient, and user-friendly, ensuring that the act of remembrance is as timeless as the memories it seeks to preserve.

Specificatons of grave headstones engraver

| NO. | Description | Value |

|---|---|---|

| 1 | Working area | 1800*2500mm |

| 2 | Feed height | 200mm |

| 3 | Transmission | X/Y rack and pinion, Z ball screw |

| 4 | Table structure | T slot with clamp |

| 5 | Spindle power | 4.5KW*2 |

| 6 | Spindle speed | 24000r/min |

| 7 | Travelling speed | 25m/min |

| 8 | Working speed | 20m/min |

| 9 | Working Delicacy | 0.005mm |

| 10 | Repositioning Accuracy | 0.05mm |

| 11 | Driving Motor | Stepper |

| 12 | Control System | DSP/Ncstudio Control System |

| 13 | Command Code | G Code*.u00*.mmg*.plt |

| 14 | Total Power | 19 KW |

| 15 | Voltage | AC380/50HZ |

| 16 | Running Environment | Temperature:0 degree~45 degree |

| 17 | Dimension | 3300*2800*2200 |