1. Introduce of Marble Cutting Machine

2. Maintenance and Serviceability of Marble Cutting machine

3. Size and Power of marble cutting machine

4. Details of Marble Cutting Machine

5. Marble Cutting Machine Specifications

6. Marble Cutting Machine Video

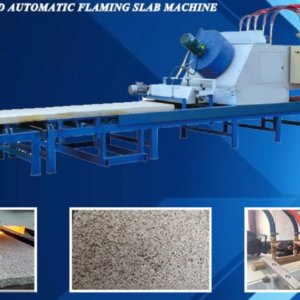

Introduce of Marble Cutting Machine

Marble Cutting Machine Bridge Saw is special designed for marble cutting. Adapt with top brand PLC system, this controling program promise customer a precious cutting with high working efficiency. The features of this marble cutting machine as follows:

1. Designed with four hydraulic steel columns, all of these steel column made with high quality steel materials to make sure most strong cutting.

2. Max Cutting thickness of this marble cutting machine is 20cm.

3. Table of this machine can have a 90 degree automatic rotation. The rotation angle can also be customed.

4. This marble cutting machine bridge saw can cutting not only marble, but also granite and other stone materials.

Maintenance and Serviceability of Marble Cutting machine:

Regular maintenance and timely servicing are essential for optimal machine performance and longevity. Marble cutting machines require periodic inspections, lubrication, and calibration to ensure accurate cutting. It is crucial to follow the manufacturer’s guidelines and consult qualified technicians for any repairs or adjustments.

Maintenance and serviceability are crucial aspects of owning and operating a Marble cutting machine. Regular maintenance and timely service ensure the machine’s optimal performance, longevity, and safe operation. Here are some key points related to maintenance and serviceability:

1. Scheduled Maintenance:

Marble cutting machines require scheduled maintenance to keep them in optimal working condition. This includes routine tasks such as cleaning, lubrication, and inspection of critical components. Regular maintenance helps prevent breakdowns, reduces the risk of costly repairs, and extends the machine’s lifespan.

2. Component Inspection:

Inspecting the machine’s components is essential to identify any signs of wear, damage, or misalignment. Critical components that should be inspected include the cutting blade, spindle, motor, belts, bearings, rails, guides, and electrical connections. Regular inspections help identify potential issues early, allowing for timely repairs or replacements.

3. Lubrication:

Proper lubrication of moving parts is vital for smooth operation and reduced friction. Marble cutting machines have various components that require lubrication, such as the cutting head, rails, gears, and bearings. It is important to follow the manufacturer’s guidelines regarding the type of lubricant to be used and the recommended lubrication intervals.

4. Electrical System:

The electrical system of the Marble cutting machine should be inspected regularly to ensure proper functioning and safety. This includes checking for loose connections, worn-out cables, and any signs of electrical malfunction. It is advisable to have a qualified electrician perform inspections and address any electrical issues.

5. Dust and Debris Management:

Marble cutting machines generate a significant amount of dust and debris during the cutting process. Proper dust and debris management is crucial for maintaining the machine’s performance and protecting its internal components. Regular cleaning of the machine’s dust collection system, filters, and workspace is necessary to prevent clogging and ensure efficient dust removal.

6. Operator Training:

Proper training of operators is essential for the safe and effective operation of the Marble cutting machine. Operators should be trained on the machine’s features, operating procedures, safety protocols, and maintenance requirements. Training should also include best practices for handling different materials, changing blades, and adjusting cutting parameters.

7. Service and Support:

Having access to reliable service and support is crucial for Marble cutting machine owners. It is important to choose a reputable manufacturer or supplier that offers responsive customer support, technical assistance, and spare parts availability. Regular servicing by qualified technicians can help address any complex issues, perform calibration, and ensure optimal machine performance.

8. Documentation and Record-Keeping:

Maintaining a comprehensive record of maintenance activities, service history, and any repairs performed is essential. This helps track the machine’s maintenance schedule, identify recurring issues, and ensure compliance with warranty requirements. Documentation also aids in troubleshooting, future maintenance planning, and potential resale or equipment appraisal.

9. Safety Measures:

Maintenance activities should always prioritize safety. Operators and maintenance personnel should follow appropriate safety protocols, such as wearing personal protective equipment (PPE), isolating power sources during maintenance, and adhering to lockout/tagout procedures. Regular safety inspections and risk assessments should be conducted to identify potential hazards and implement necessary safety measures.

By following a proactive maintenance and service routine, Marble cutting machine owners can maximize the machine’s uptime, minimize unexpected breakdowns, and ensure the safety of operators. Regular maintenance and timely service not only optimize the machine’s performance but also contribute to its longevity, protecting the owner’s investment and promoting efficient production workflows.

Size and Power of marble cutting machine:

Marble cutting machines come in various sizes and power configurations to accommodate different cutting needs. Smaller machines are suitable for small to medium-sized fabrication shops or specific projects, while larger machines are designed for high-volume production. The power of the machine’s motor determines the cutting speed and its ability to handle different stone materials.

Size and power are key considerations when selecting a Marble cutting machine. The size refers to the physical dimensions and working area of the machine, while power refers to the motor capacity and cutting capabilities. Here are some points to consider regarding size and power in the context of Marble cutting machines:

1. Machine Size:

Marble cutting machines come in a range of sizes to accommodate different material sizes and production requirements. The size of the machine will determine the maximum dimensions of the materials it can handle. Smaller machines may be suitable for smaller workshops or limited production needs, while larger machines are capable of handling larger slabs or higher volumes of cutting.

2. Working Area:

The working area of a Marble cutting machine refers to the space available for positioning and cutting materials. It is typically defined by the length and width of the machine’s worktable or cutting bed. The working area should be sufficient to accommodate the largest materials to be cut. Consider the size of the slabs or pieces you typically work with to ensure the machine’s working area meets your requirements.

3. Motor Power:

The motor power of a Marble cutting machine determines its cutting capabilities and efficiency. It is typically measured in horsepower (HP) or kilowatts (kW). A higher motor power enables the machine to cut through tougher or denser materials with greater ease and speed. When choosing a machine, consider the types of materials you will be working with and their hardness or density to determine the appropriate motor power.

4. Cutting Depth and Blade Diameter:

The size and power of the Marble cutting machine also determine the cutting depth and maximum blade diameter it can accommodate. The cutting depth refers to the thickness of the material that can be cut in a single pass. Larger machines with higher power can handle thicker materials. The blade diameter determines the maximum width of the cut. Machines with larger blade diameters allow for wider cuts and can accommodate larger slabs.

5. Space and Installation Considerations:

The size and power of the Marble cutting machine should align with the available space in your workshop or production facility. Consider the machine’s dimensions, including its length, width, and height, to ensure it can be properly installed and operated in your workspace. Additionally, the power requirements of the machine should be compatible with your electrical infrastructure to ensure safe and reliable operation.

6. Production Capacity:

The size and power of the machine also impact its production capacity. Larger machines with higher power can typically handle larger volumes of cutting and may offer faster cutting speeds. Consider your production requirements, such as the number of cuts needed per day or per hour, to determine the appropriate size and power of the machine that can meet your production demands.

7. Future Expansion:

When selecting a Marble cutting machine, it is important to consider potential future growth and expansion. Assess whether the size and power of the machine can accommodate any anticipated changes in your production needs or the types of materials you may work with in the future. Investing in a machine with some room for growth can help avoid the need for premature upgrades or replacements.

Size and power are critical factors in selecting a bridge saw machine that meets your specific needs and production requirements. By carefully evaluating the size, working area, motor power, cutting depth, and blade diameter, you can choose a machine that can handle your desired materials, deliver efficient cutting performance, and support your production goals effectively.

Details of Marble Cutting Machine

Marble Cutting Machine Specifications

| Item Name | Unit | Value |

|---|---|---|

| Blade Diameter | mm | 600 |

| Horizontal Travel | mm | 3200 |

| Longitudinal Travel | mm | 3200 |

| Vertical Travel | mm | 300 |

| Main Motor | KW | 18.5 |

| Total Power | KW | 21.5 |

| Size of table | mm | 3200*2000 |

| Table Rotation | n° | 90 |

| Machine overall | mm | 6000*5000*2800 |

| Weight | T | 5.6 |