1. What is a Stone Gantry Block Cutting Machine

2. Differences between Stone Gantry Block Cutting Machine and Hydraulic Block Cutting Machine

3. Advantages and Disadvantages of Stone Gantry Block Cutting Machine

4. Why You Need a Stone Gantry Block Cutting Machine

5. Features of stone gantry block cutting machine

6. Cutting Efficiency of Stone Gantry Block Cutting Machine

7. Specifications of Stone Gantry Block Cutting Machine

In the ever-evolving world of stone cutting technology, the stone gantry block cutting machine has emerged as a pinnacle of precision and efficiency. Designed to meet the demands of the modern stone processing industry, this machine has become a cornerstone in enhancing the quality and speed of block cutting operations.

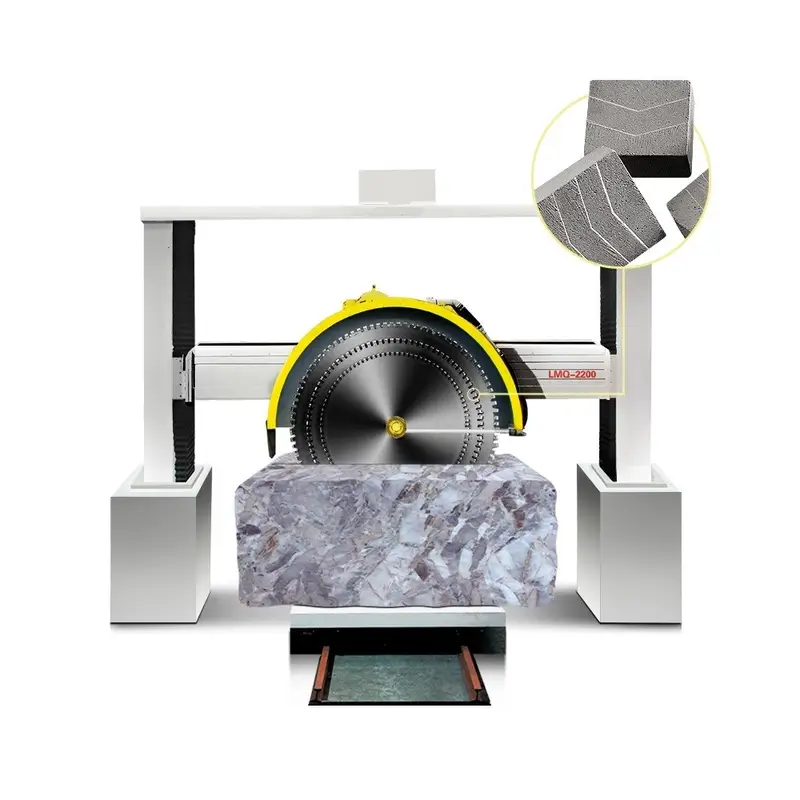

1. What is a Stone Gantry Block Cutting Machine:

A stone gantry block cutting machine is a specialized piece of equipment used in the stone processing industry to precisely cut large stone blocks into slabs or smaller pieces. It is characterized by its robust gantry structure that spans the cutting area, providing stability and support during the cutting process. This machine is equipped with advanced cutting tools and automation features to ensure accuracy and efficiency in the stone cutting process.

2. Differences between Stone Gantry Block Cutting Machine and Hydraulic Block Cutting Machine:

2.1 Machine Structure:

One of the key distinctions between a stone gantry block cutting machine and a hydraulic block cutting machine lies in their structures. The gantry block cutting machine features a sturdy gantry framework that supports the cutting tools and ensures consistent and precise cutting across the entire surface of the stone block. In contrast, hydraulic block cutting machines typically have a different structural setup, often with a more compact design.

2.2 Screw System and Hydraulic System:

The choice of cutting mechanism is another significant difference between the two types of machines. The stone gantry block cutting machine utilizes a screw system to drive the cutting tools along the stone surface. This system allows for precise control and consistent cutting depth. On the other hand, hydraulic block cutting machines rely on hydraulic systems to power the cutting tools, offering a different set of advantages and limitations.

3. Advantages and Disadvantages of Stone Gantry Block Cutting Machine:

Advantages:

a. Precision: The gantry structure ensures stability, resulting in precise and consistent cutting.

b. Versatility: Suitable for a wide range of stone types and sizes.

c. Automation: Integrated automation features enhance efficiency and reduce labor requirements.

d. Speed: The gantry block cutting machine is known for its high-speed cutting capabilities.

Disadvantages:

a. Initial Investment: Gantry block cutting machines may have a higher upfront cost compared to some alternatives.

b. Maintenance: The complex machinery requires regular maintenance to ensure optimal performance.

4. Why You Need a Stone Gantry Block Cutting Machine:

Investing in a stone gantry block cutting machine is essential for businesses aiming to stay competitive in the stone processing industry. The machine’s precision, versatility, and speed contribute to increased productivity and higher-quality stone products. Whether you are dealing with granite, marble, or other natural stones, the gantry block cutting machine is a reliable and indispensable tool that ensures efficient and accurate stone cutting operations, ultimately leading to enhanced customer satisfaction and business success.

5. Features of stone gantry block cutting machine

The stone gantry block cutting machine boasts a range of features that collectively contribute to its efficiency, precision, and versatility in the stone processing industry. Here are more detailed insights into the key features of this advanced cutting equipment:

1. **Gantry Structure:**

– *Stability:* The robust gantry structure provides a stable foundation, minimizing vibrations during cutting operations and ensuring consistent, high-quality cuts.

– *Spanning Capability:* The gantry spans the entire cutting area, allowing for the processing of large stone blocks with precision.

2. **Cutting Tools and Blades:**

– *Diamond Blades:* These machines typically use diamond-tipped blades for cutting. Diamond is one of the hardest materials, ensuring durability and longevity of the cutting tools.

– *Multi-Blade Configurations:* Some models offer the flexibility of using multiple blades simultaneously, increasing cutting efficiency and reducing processing time.

3. **Screw System:**

– *Precision Control:* The screw system enables precise control over the movement of cutting tools along the stone surface, ensuring uniform cuts and controlled cutting depths.

– *Synchronization:* Synchronized movement of screws enhances overall cutting efficiency, especially in large-scale stone cutting operations.

4. **Automation and CNC Technology:**

– *Computer Numerical Control (CNC):* Advanced automation features, often driven by CNC technology, enable programmable and repeatable cutting processes.

– *Optimized Workflows:* Automation streamlines the workflow, reducing manual intervention, minimizing errors, and contributing to overall efficiency.

5. **Versatility:**

– *Material Compatibility:* Stone gantry block cutting machines are versatile and can handle various types of stones, including granite, marble, limestone, and more.

– *Size Adjustment:* Adjustable settings allow for cutting stones of different sizes and thicknesses, catering to diverse industry requirements.

6. **Hydraulic System:**

– *Hydraulic Power:* Some models integrate hydraulic systems to power specific components, enhancing cutting force and efficiency.

– *Pressure Control:* Hydraulic systems allow for precise control of cutting pressure, adapting to different stone densities and hardness.

7. **Safety Features:**

– *Emergency Stop:* Equipped with emergency stop mechanisms to ensure the safety of operators and prevent accidents.

– *Overload Protection:* Automatic systems to prevent overload, protecting the machine and ensuring prolonged operational life.

8. **Water Cooling System:**

– *Temperature Regulation:* Water cooling systems prevent overheating of blades during prolonged cutting sessions, maintaining optimal cutting performance.

9. **User Interface:**

– *Intuitive Controls:* User-friendly interfaces make operation straightforward, with touchscreens or control panels allowing operators to monitor and adjust parameters easily.

10. **Maintenance and Diagnostics:**

– *Diagnostic Tools:* Integrated diagnostic systems provide real-time information on machine status, facilitating proactive maintenance.

– *Easy Maintenance:* Modular design and accessible components simplify routine maintenance tasks, minimizing downtime.

In summary, the stone gantry block cutting machine is a comprehensive solution that combines stability, precision, versatility, and automation, making it an indispensable tool for businesses in the stone processing industry. These features collectively contribute to enhanced cutting efficiency, increased productivity, and the production of high-quality stone products.

6. Cutting Efficiency of Stone Gantry Block Cutting Machine

The cutting efficiency of a stone gantry block cutting machine is a standout feature that significantly contributes to its popularity in the stone processing industry. The efficiency of this machine is a result of several key design elements and technological advancements that work in tandem to streamline the cutting process.

One of the primary contributors to the cutting efficiency is the machine’s gantry structure. The robust gantry, spanning the cutting area, ensures stability and minimizes vibrations during the cutting operation. This stability is paramount in achieving precise and consistent cuts across the entire surface of large stone blocks. The gantry’s rigid framework also facilitates high-speed cutting without compromising accuracy.

The screw system employed by the stone gantry block cutting machine further enhances its cutting efficiency. This system allows for precise control over the movement of the cutting tools, ensuring a uniform and controlled cutting depth. The synchronized movement of the screws ensures that each pass of the cutting tools contributes to the overall efficiency of the process.

Automation features play a pivotal role in optimizing cutting efficiency. Modern stone gantry block cutting machines are often equipped with advanced automation systems that streamline the workflow. These systems include features such as computer numerical control (CNC) technology, which allows for programmable and repeatable cutting processes. Automation not only reduces the margin of error but also enables continuous operation, leading to higher overall efficiency.

The versatility of the stone gantry block cutting machine also contributes to its efficiency. It can handle a wide range of stone types and sizes, accommodating the diverse needs of the stone processing industry. This versatility eliminates the need for multiple machines for different materials, streamlining the production process and improving overall efficiency.

In conclusion, the cutting efficiency of a stone gantry block cutting machine is a result of its stable gantry structure, precision-oriented screw system, advanced automation features, and versatility. Businesses in the stone processing industry benefit from the machine’s ability to deliver high-speed, accurate, and consistent cuts, ultimately increasing productivity and contributing to a more efficient and cost-effective production process.

7. Specifications of Stone Gantry Block Cutting Machine