1. Introduction

2. Overview

3. Features and Components

4. Precision and Efficiency

5. Versatility

6. Applications

8. Advantages and Benefits

9. Maintenance and Care

Introduction:

In the world of stone cutting, precision and efficiency are paramount. One machine that has been making waves in the industry is the stone marble horizontal slicing machine. This state-of-the-art equipment has transformed the way stone cutting is done, offering unparalleled accuracy, speed, and versatility. In this comprehensive article, we will delve into the different dimensions of this machine, providing readers with a full understanding of its features, benefits, and applications.

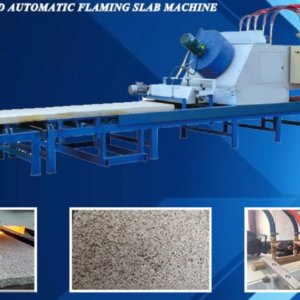

Overview:

The stone marble horizontal slicing machine is a cutting-edge piece of equipment designed specifically for slicing large marble blocks horizontally. It utilizes advanced technology and innovative mechanisms to ensure precise and efficient cutting. With its robust construction and high-performance capabilities, this machine has become an indispensable tool in the stone cutting industry.

Features and Components:

Cutting Blade:

The machine is equipped with a high-quality diamond cutting blade, specifically designed to cut through dense marble blocks smoothly and accurately. The blade’s composition and design allow for optimal performance and longevity, ensuring consistent and precise cuts throughout its lifespan.

Control Panel:

An intuitive control panel allows operators to easily adjust cutting parameters such as speed, depth, and direction. The user-friendly interface provides real-time feedback, enabling operators to make precise adjustments for optimal cutting results.

Conveyor System:

The machine incorporates a conveyor system to transport the marble blocks smoothly along the cutting path, ensuring consistent and uniform slicing. The conveyor is designed to handle heavy loads and maintain stability during the cutting process.

Water Cooling System:

To prevent overheating and maintain blade performance, a water cooling system is integrated into the machine. The water circulates around the blade, dissipating heat generated during cutting and ensuring efficient operation. This system also helps to minimize dust and debris, providing a cleaner and safer working environment.

Safety Features:

Various safety features, including emergency stop buttons and protective covers, ensure operator safety during operation. The machine is equipped with sensors that detect any abnormalities or potential hazards, automatically stopping the cutting process to prevent accidents. Protective covers and barriers provide additional protection by preventing direct contact with moving parts.

Precision and Efficiency:

The stone marble horizontal slicing machine offers unparalleled precision in cutting marble blocks. The advanced technology and precise engineering of the machine enable accurate horizontal slicing with minimal material wastage. The cutting blade’s high rotational speed, combined with the machine’s stability, ensures clean and precise cuts, resulting in high-quality finished products.

The machine’s high cutting speed significantly reduces production time, improving overall efficiency and productivity. With the ability to slice large marble blocks in a fraction of the time compared to traditional methods, this machine allows manufacturers to meet tight deadlines and increase their output. The precise cutting also minimizes the need for additional finishing processes, saving time and resources.

Versatility:

This machine is not limited to cutting marble blocks; it can also be used for other types of stones such as granite and limestone. Its adjustable cutting parameters allow for customization, enabling operators to achieve different thicknesses and sizes according to specific project requirements. Whether it’s for large-scale construction projects or intricate artistic designs, the stone marble horizontal slicing machine offers versatility that caters to various applications.

Applications:

Construction Industry:

The stone marble horizontal slicing machine is widely used in the construction industry for producing slabs, tiles, and other stone products used in flooring, countertops, and wall cladding. Its ability to cut large blocks into precise dimensions makes it an essential tool for architects, contractors, and designers who require high-quality stone materials for their projects.

Art and Sculpture:

Artists and sculptors benefit from the precision and versatility of this machine, as it allows them to create intricate designs and shapes from marble and other stones. The machine’s ability to cut with exceptional accuracy enables artists to bring their creative visions to life, whether it’s a large-scale sculpture or a finely detailed artwork.

Restoration and Conservation:

The stone marble horizontal slicing machine plays a crucial role in the restoration and conservation of historical buildings and monuments. By accurately replicating damaged or missing stone elements, this machine helps preserve the architectural heritage of various structures. Its ability to match the original stone’s texture, color, and pattern ensures seamless integration and authenticity in restoration projects.

Manufacturing and Industrial Applications:

Beyond construction and art, the stone marble horizontal slicing machine finds applications in various manufacturing and industrial sectors. It is used in the production of countertops, vanity tops, tabletops, and other stone products for residential and commercial purposes. Additionally, the machine’s precise cutting capabilities make it suitable for creating custom stone components for machinery, equipment, and specialized tools.

Advantages and Benefits:

Enhanced Efficiency:

The stone marble horizontal slicing machine significantly improves operational efficiency by reducing production time and minimizing material wastage. Its high cutting speed, combined with precise control over cutting parameters, allows manufacturers to streamline their processes and meet demanding project deadlines.

Superior Precision:

With its advanced technology and precise engineering, this machine ensures accurate and consistent cutting results. The ability to achieve precise dimensions and clean cuts enhances the overall quality of finished stone products, meeting the high standards expected in the industry.

Increased Productivity:

By automating the cutting process and optimizing cutting parameters, the machine enables manufacturers to increase their productivity. The ability to slice large blocks quickly and efficiently translates into higher output, leading to greater profitability for businesses.

Cost Savings:

The precise cutting capabilities of this machine minimize material wastage, resulting in cost savings for manufacturers. Additionally, its efficiency and productivity improvements reduce labor costs and allow businesses to allocate resources more effectively.

Safety and Operator Comfort:

The stone marble horizontal slicing machine is equipped with various safety features to ensure operator safety during operation. Emergency stop buttons, protective covers, and sensors contribute to a safer working environment, reducing the risk of accidents and injuries. The machine’s ergonomic design also prioritizes operator comfort, minimizing fatigue during prolonged use.

Maintenance and Care:

To ensure optimal performance and longevity of the stone marble horizontal slicing machine, regular maintenance and care are essential. Proper blade maintenance, including periodic sharpening or replacement, is crucial to maintain cutting precision. The water cooling system should be regularly cleaned and checked for any blockages or leaks.

Routine inspections of all components, including the conveyor system, control panel, and safety features, should be conducted to identify any signs of wear or damage. Lubrication of moving parts and adjustment of cutting parameters should be performed as recommended by the manufacturer.

The stone marble horizontal slicing machine has revolutionized the stone cutting industry with its precision, efficiency, and versatility. Its advanced technology and innovative features have made it an indispensable tool for manufacturers, artists, and restoration experts alike. With its ability to deliver accurate cuts, high productivity, and cost savings, this machine has become the go-to solution for achieving superior quality stone products. Embracing this cutting-edge technology ensures businesses stay at the forefront of the stone cutting industry, meeting the ever-growing demands of customers worldwide.