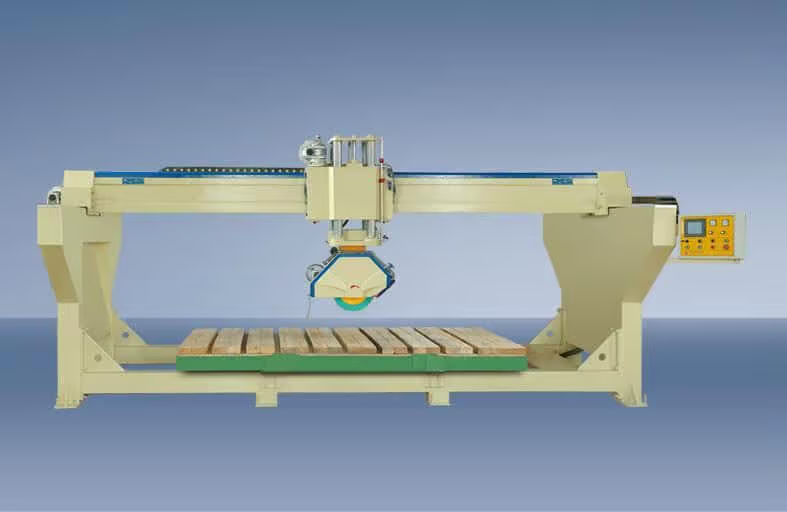

Bridge Saw Machines

Our bridge saw machines are mainly includes regular bridge saw for straight cutting, marble granite miter saw machine, 5 Axis CNC bridge saw machine, 45 degree tilting chamfering bridge saw. MosCut bridge saw machine are your best choice for stone fabricator and decorative industry.