Industrial Stone Cutting Machine for Sale | Reliable Stone Cutter Manufacturer

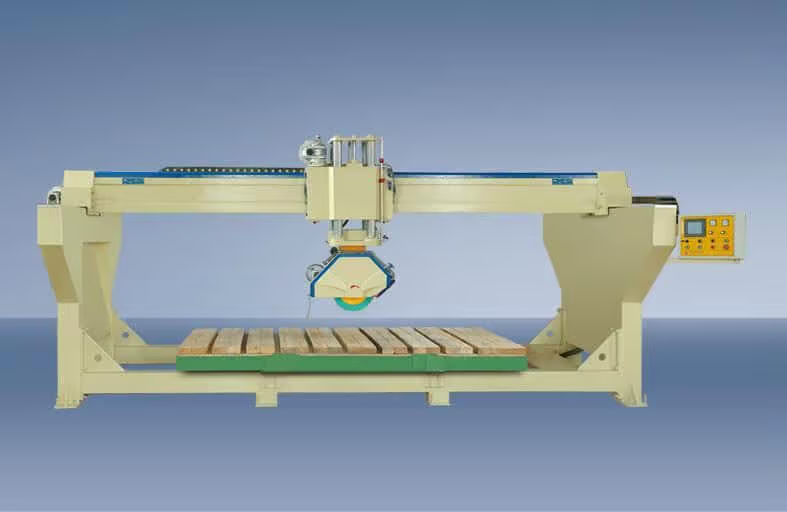

Transform your stone cutting machine with MOSCUT. Your trusted partner for high-performance industrial stone cutting technology. We specialize in engineering durable, high-precision stone cutter machines designed to handle the toughest granite, marble, and quartz slabs with ease. From CNC saws to manual cutters, we provide efficient stone.